White Paper | Differences Between IEEE Stationary Battery

Verify that the station battery can perform as manufactured by conducting a performance or modified performance capacity (load) test of the entire battery bank. What does IEEE 1188

Get a quote

How many tons of energy storage batteries are used

To apply an accurate energy storage metric, one should delve into the average capacity of batteries deployed in these installations. Roughly,

Get a quote

Comparison of LiFePO4 battery and lead-acid battery in base

Explore the critical considerations in selecting batteries for base stations. This comparison between LiFePO4 and lead-acid batteries delves into power consumption, backup time, and

Get a quote

From communication base station to emergency

In the low temperature environment, although the battery capacity will be reduced, but by equipped with heating devices or using special low

Get a quote

Five Core Advantages of Lithium Batteries for Telecommunication Base

The Five Core Advantages of EverExceed Telecom Base Station Lithium Batteries Compared with traditional lead-acid batteries, EverExceed lithium batteries offer remarkable advantages,

Get a quote

Comparison of LiFePO4 battery and lead-acid battery in base station

Explore the critical considerations in selecting batteries for base stations. This comparison between LiFePO4 and lead-acid batteries delves into power consumption, backup time, and

Get a quote

Lead-Acid Battery Lifetime Estimation using Limited Labeled

Abstract—Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as well as to optimize operational expenses.

Get a quote

Overview of Telecom Base Station Batteries

In terms of technical realization, telecom energy storage systems usually adopt lead-acid batteries or lithium ion solar batteries as the energy storage

Get a quote

What Powers Telecom Base Stations During Outages?

Telecom batteries for base stations are backup power systems using valve-regulated lead-acid (VRLA) or lithium-ion batteries. They ensure uninterrupted connectivity

Get a quote

Battery Sizing Considerations IEEE 2020

125Vdc: 105Vdct to 140Vdc *Should be based on equipment connected to the battery. Battery capacities and discharge ratings are published based on a certain temperature, usually

Get a quote

Understanding Backup Battery Requirements for Telecom Base Stations

Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is crucial for network stability and

Get a quote

Building a battery bank using amp hours batteries

In this article we''ll look at different ways to build a battery bank (and ways not to) for amp hour rated batteries (and ways not to). In the illustrations we use sealed lead acid

Get a quote

Grid-Scale Battery Storage: Frequently Asked Questions

What are the key characteristics of battery storage systems? Rated power capacity is the total possible instantaneous discharge capability (in kilowatts [kW] or megawatts [MW]) of the

Get a quote

Battery Sizing Calculation | Solved Example

Learn about battery sizing calculation for applications like Uninterrupted Power Supply (UPS), solar PV systems, telecommunications, and other auxiliary services in power systems, along

Get a quote

Understanding the Capacity and Performance of Large Lead Acid

The capacity of a lead acid battery, measured in amp-hours (Ah), represents its ability to deliver a constant current over a specific time. At its core, capacity is determined by the number and

Get a quote

Battery Sizing Calculation | Solved Example

Learn about battery sizing calculation for applications like Uninterrupted Power Supply (UPS), solar PV systems, telecommunications, and other auxiliary

Get a quote

SECTION 6: BATTERY BANK SIZING PROCEDURES

Smallest cell capacity available for selected cell type that satisfies capacity requirement, line 6m, when discharged to per-cell EoD voltage, line 9d or 9e, at functional hour rate, line 7. OR, if no

Get a quote

Picking the best battery for portable Ham Radio

A common battery, like this 30 amp hour lead acid AGM battery would give you a few hours of operation time before its capacity would drop to

Get a quote

How many tons of energy storage batteries are used in base stations

To apply an accurate energy storage metric, one should delve into the average capacity of batteries deployed in these installations. Roughly, these batteries range from 5

Get a quote

BU-214: Summary Table of Lead-based Batteries

Lead acid works best for standby applications that require few deep-discharge cycles and the starter battery fits this duty well. Table 1 summarizes the characteristics of lead

Get a quote

Understanding the Capacity and Performance of Large Lead Acid Batteries

The capacity of a lead acid battery, measured in amp-hours (Ah), represents its ability to deliver a constant current over a specific time. At its core, capacity is determined by the number and

Get a quote

Which Rack Batteries Are Most Reliable for Telecom Base Stations?

Their wide operating temperature range (-20°C to 60°C) and near-zero maintenance reduce downtime in remote base stations. Telecom applications demand

Get a quote

BU-214: Summary Table of Lead-based Batteries

Lead acid works best for standby applications that require few deep-discharge cycles and the starter battery fits this duty well. Table 1

Get a quote

INDUSTRIAL LEAD ACID BATTERIES: TYPES AND THEIR

The lead acid battery comprises of two chemically dissimilar lead based plates in a dilute sulphuric acid solution. The positive plate contains lead dioxide PbO, and the negative plate

Get a quote

6 FAQs about [Capacity of base station lead-acid batteries]

What are the characteristics of lead-acid battery?

The lead-acid battery performance is comparatively stable but reduces with the passage of time. Temperature correction factor: The battery cells capacity is generally provided for a standardized temperature which is 25oC and if it varies somewhere with the installation temperature, a correction factor is needed to implement.

How long does a lead-acid battery last?

This is the primary factor that limits battery lifetime. Deep-cycle lead-acid batteries appropriate for energy storage applications are designed to withstand repeated discharges to 20 % and have cycle lifetimes of ∼2000, which corresponds to about five years. Battery capacity is reported in amp-hours (Ah) at a given discharge rate.

What is a duty cycle for a lead acid battery?

The standard recommends a duty cycle be drawn showing the anticipated loads (in [ [Ampere]] or power) for the required duration of battery backup time. IEEE 485 Std. Recommended Practice for Sizing Lead Acid Batteries for Stationary Applications - Typical Duty Cycle Considerations

Is a lead acid battery a good choice?

The lead acid battery maintains a strong foothold as being rugged and reliable at a cost that is lower than most other chemistries. The global market of lead acid is still growing but other systems are making inroads. Lead acid works best for standby applications that require few deep-discharge cycles and the starter battery fits this duty well.

How does a lead-acid battery cell work?

A lead-acid battery cell consists of a positive electrode made of lead dioxide (PbO 2) and a negative electrode made of porous metallic lead (Pb), both of which are immersed in a sulfuric acid (H 2 SO 4) water solution. This solution forms an electrolyte with free (H+ and SO42-) ions. Chemical reactions take place at the electrodes:

What is the voltage of a lead-acid cell?

The voltage of a typical single lead-acid cell is ∼ 2 V. As the battery discharges, lead sulfate (PbSO 4) is deposited on each electrode, reducing the area available for the reactions. Near the fully discharged state (see Figure 3), cell voltage drops, and internal resistance increases.

Guess what you want to know

-

How much is the photovoltaic power generation capacity of lead-acid batteries in Canadian communication base stations

How much is the photovoltaic power generation capacity of lead-acid batteries in Canadian communication base stations

-

How much does a set of lead-acid batteries for a communication base station cost

How much does a set of lead-acid batteries for a communication base station cost

-

How to charge base station energy storage batteries

How to charge base station energy storage batteries

-

Burkina Faso communication base station lead-acid battery bidding

Burkina Faso communication base station lead-acid battery bidding

-

What are the advantages of base station batteries

What are the advantages of base station batteries

-

Does Ireland s 5G base station use lithium batteries

Does Ireland s 5G base station use lithium batteries

-

Peak-shaving and valley-filling technology for communication base station batteries

Peak-shaving and valley-filling technology for communication base station batteries

-

Lead-acid battery manufacturing ESS power base station container

Lead-acid battery manufacturing ESS power base station container

-

The latest planning of lead-acid batteries for Cyprus communication base stations

The latest planning of lead-acid batteries for Cyprus communication base stations

-

Barbados photovoltaic communication base station lead-acid battery

Barbados photovoltaic communication base station lead-acid battery

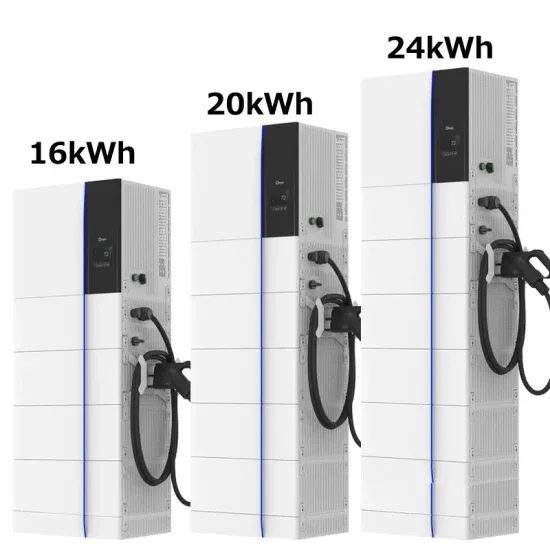

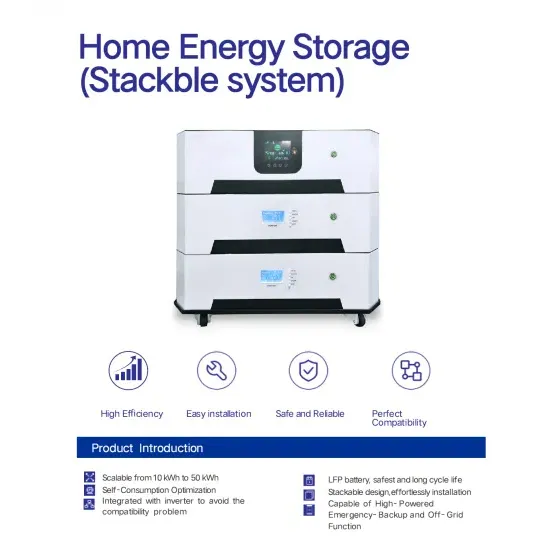

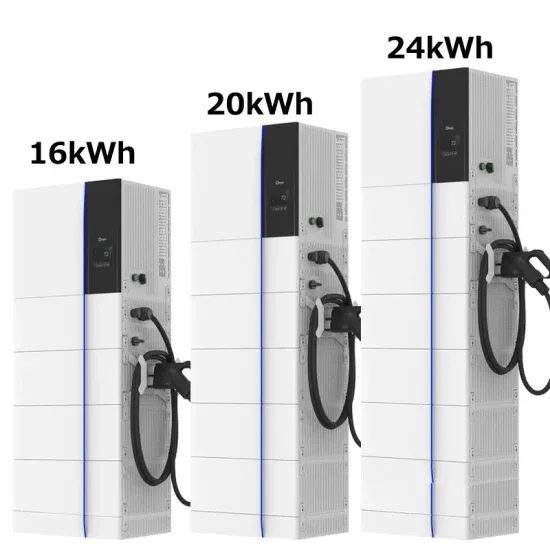

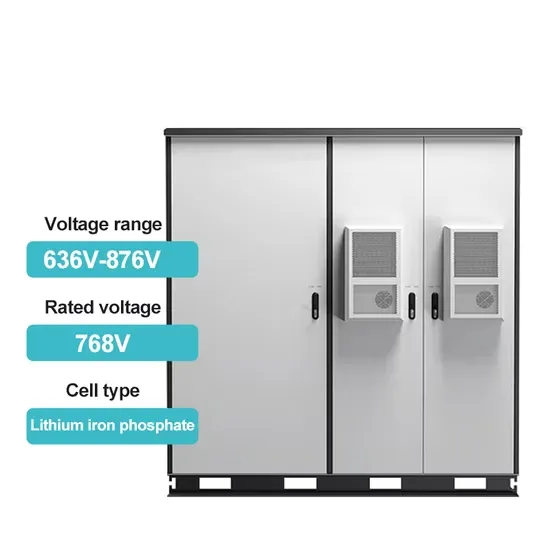

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.