How to Plan a Successful Energy Construction Project

These Ten Steps May Help Power Companies Avoid Headaches, Delays, Higher Costs, and Legal Complications, Resulting in a Successful Construction Project.

Get a quote

Top 9 Commercial Construction Projects in May 2025 & How

Labor remains one of the largest expenses in construction, often accounting for up to 40% of total project costs. This includes direct wages, overtime, insurance, benefits, and the

Get a quote

20-02-18 OSBCTC-Rye MOU Press Release

~ Southern Oregon Building and Construction Trades Council Inks MOU with Developer ~ PORTLAND, Oregon, February 18, 2020—The Southern Oregon Building and Construction

Get a quote

Technologies and economics of electric energy storages in power

As fossil fuel generation is progressively replaced with intermittent and less predictable renewable energy generation to decarbonize the power system, Electrical energy

Get a quote

Power construction projects

The existence and development of adequate power infrastructure is essential to deliver affordable and reliable energy to the businesses and consumers. Power Technology''s power

Get a quote

Construction cost of new energy storage

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries, vanadium redox flow batteries,

Get a quote

Study on the investment and construction models and value

To address the issue, this paper proposes investment and construction models for shared energy-storage that aligns with the present stage of energy storage development.

Get a quote

Energy Storage Station Construction Costs | EB BLOG

This article meticulously examines the construction costs of energy storage stations, shedding light on the factors that influence these costs. This

Get a quote

Top 9 Commercial Construction Projects in May 2025 & How Temp Labor

Labor remains one of the largest expenses in construction, often accounting for up to 40% of total project costs. This includes direct wages, overtime, insurance, benefits, and the

Get a quote

List of energy storage power plants

This is a list of energy storage power plants worldwide, other than pumped hydro storage. Many individual energy storage plants augment electrical grids by

Get a quote

The Energy Storage Market in Germany

The German Energy Revolution The German energy storage market has experienced a mas-sive boost in recent years. This is due in large part to Ger-many''s ambitious energy transition

Get a quote

Capital Cost and Performance Characteristics for Utility

Unless noted otherwise, the estimates assume that the EPC contractor cost will include procurement of equipment, materials, and all construction labor associated with the project.

Get a quote

A Model for Forecasting Investment Trends in Pumped Storage Power

As a large-scale regulating power source, pumped storage power station is of great significance for the safe and stable operation of power system. Pumped storage power

Get a quote

Energy Storage Labor Cost: The Hidden Driver Behind the

Why Labor Costs Are Stealing the Spotlight in the Energy Storage Circus While lithium prices and battery tech dominate energy storage headlines, there''s an

Get a quote

Energy storage labor construction

How do energy storage contracts work? For standalone energy storage contracts,these are typically structured with a fixed monthly capacity payment plus some variable cost per

Get a quote

SECTION 3: PUMPED-HYDRO ENERGY STORAGE

2 Introduction 3 Potential Energy Storage Energy can be stored as potential energy Consider a mass, 乭⩋, elevated to a height, Its potential energy increase is h where 乭⩋ is h

Get a quote

How long does it take to build an energy storage power station?

The category of technology employed in energy storage plays an essential role in determining how long it takes to complete a power station. Various types exist, including

Get a quote

Energy storage power station construction implementation

The second CAES power station, located in McIntosh, AL, USA, was completed in 1991, with a designed peak load capacity of 110 MW for 26 h [36]. At present, the main means of power

Get a quote

How much is the construction price of energy storage power station

The construction price of energy storage power stations varies significantly based on several key factors, including location, technology type, capacity requirements, and

Get a quote

Mayor Garcetti Celebrates Final Approval of Largest

LOS ANGELES — Mayor Eric Garcetti today announced unanimous City Council approval of power purchase agreements for the Eland

Get a quote

How much does energy storage construction cost?

Examining the current landscape of energy storage construction costs necessitates an understanding of the various technologies and their

Get a quote

Energy Storage Power Station Costs: Breakdown & Key Factors

3 days ago· How does location affect energy storage station costs? Location directly impacts construction expenses such as land, labor, and permitting. It also influences long-term

Get a quote

Energy Storage Station Construction Costs | EB BLOG

This article meticulously examines the construction costs of energy storage stations, shedding light on the factors that influence these costs. This in-depth analysis

Get a quote

2020 Grid Energy Storage Technology Cost and

PSH is a mature technology that includes pumping water from a lower reservoir to a higher one where it is stored until needed. When released, the water from the upper reservoir flows back

Get a quote

How much does energy storage construction cost? | NenPower

Examining the current landscape of energy storage construction costs necessitates an understanding of the various technologies and their respective pricing structures.

Get a quote

Pumped Storage Hydropower FAST Commissioning

Pumped Storage Hydropower FAST Commissioning Technical Analysis Summary Report Overview: This report is designed to address barriers and solutions to modern pumped

Get a quote

6 FAQs about [Energy storage power station project construction labor volume]

How much does the Goldendale energy storage project cost?

The Goldendale Energy Storage Project has a head of 2,400 feet and is expected to cost $1,800/kW for C&I. Higher head for the project also reduced tunnel excavation costs due to the fact the pump/turbine centerline depth below the lower reservoir bottom decreased with increasing head (Miller, 2020a).

How much does a power plant cost?

Assuming these costs do not include substation/switchgear and transmission lines, the total costs are at the lower end of the $2,500 to 3,500/kW range provided in conversations with developers (Manwaring et al., 2020; Miller, 2020a).

How much does a powerhouse cost?

The sum of the powerhouse C&I and electromechanical costs comes out to $1,500/kW and is greater than the $1,260/kW reported in the 2012 Black & Veatch report, but the total project cost is similar as the latter assumed indirect costs to be 55% of direct costs (Black & Veatch, 2012).

How much does a 10 hour power plant cost?

For a 10-hour plant, the reservoir cost was found to be $104/kWh, higher than the $77/kWh without contingency fee and very close to the $103/kWh inclusive of contingency fees obtained from conversations with a PSH developer (Miller, 2020a).

What is the average MW capacity of a PSH plant?

The average MW capacity level for PSH plants has increased from 600 MW in 1973, to 1,400 MW in 1991, to > 2,000 MW today, with the current largest plant in the US being 3,000 MW (Bath County Pumped Storage Station, Virginia).

What is routine labor in a power plant?

Routine labor includes the regular maintenance of the equipment as recommended by the equipment manufacturers. This includes maintenance of pumps, compressors, transformers, instruments, controls, and valves. The power plant’s typical design is such that routine labor activities do not require a plant outage.

Guess what you want to know

-

Cambodia Siem Reap Energy Storage Power Station Construction Project

Cambodia Siem Reap Energy Storage Power Station Construction Project

-

Qatar Energy Storage Power Station Construction Project

Qatar Energy Storage Power Station Construction Project

-

Ireland energy storage power station construction project

Ireland energy storage power station construction project

-

Laos Energy Storage Power Station Project Construction

Laos Energy Storage Power Station Project Construction

-

South Korea Energy Storage Power Station Construction Project

South Korea Energy Storage Power Station Construction Project

-

Costa Rica Communication Base Station Energy Storage System Construction Project

Costa Rica Communication Base Station Energy Storage System Construction Project

-

Independent energy storage power station construction

Independent energy storage power station construction

-

Morocco Casablanca Energy Storage Power Station Grid Connection Project

Morocco Casablanca Energy Storage Power Station Grid Connection Project

-

Germany grid-side energy storage power station project

Germany grid-side energy storage power station project

-

Is the energy storage power station project reliable

Is the energy storage power station project reliable

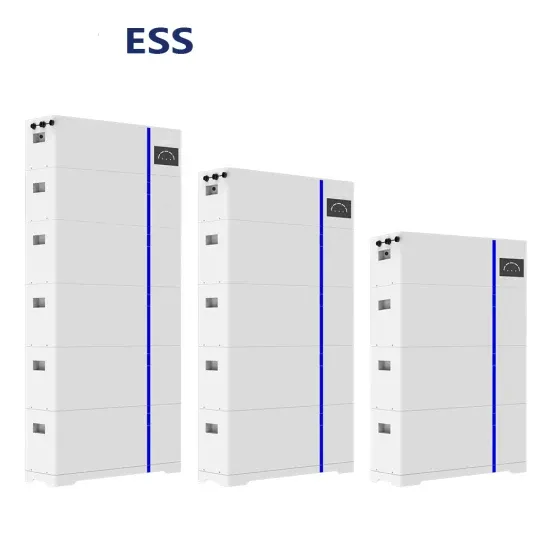

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.