Enabling Smarter DC Link Discharge in EV Traction Inverters

Explore the live demonstration of the GD3162''s DC Link discharge feature and discover how NXP is enabling smarter, safer and more efficient EV systems through its latest

Get a quote

TPS63700 DC-DC Inverter datasheet (Rev

The design of the inverter can be adapted to different output voltage and load current needs by choosing external components appropriately. The following design procedure is adequate for

Get a quote

SLAAEL5 Application brief | TI

This discharge process aims to safeguard occupants or maintenance personnel, minimizing the risk of personal injury from contact with live components or potential fire hazards. Depending

Get a quote

Bidirectional (V2H and V2G) EV Chargers Guide (2025)

DC EV charger and 2. an external inverter. Since the Sigen inverter is already certified, the system as a whole is certified and compliant. The other

Get a quote

Tesla V2L Discharge Device | DC to AC Adapter for Model

This specialized product is designed to extract DC power directly from Tesla''s fast-charging port and then convert it into safe, usable AC power using a built-in high-performance

Get a quote

How to Reduce the Power Resistor for DC-Link Discharge in

The DC-Link capacitor is a part of every traction inverter and is positioned in parallel with the high-voltage battery and the power stage (see Figure 1). The DC-Link capacitor has several

Get a quote

A DC-Link Hybrid Active Discharge Scheme for

This paper examines the limitations of traditional discharge techniques and proposes a novel hybrid discharge solution that combines the

Get a quote

Designing a Robust Traction Inverter Redundant Power

The traction inverter efficiently converts DC power from a high-voltage battery to alternating phases of power needed to drive multi-phase motors. Galvanic isolation is required to protect

Get a quote

AC vs DC disconnects: choosing safely for hybrid inverters

4 days ago· Power up safety with smart AC DC disconnects for hybrid inverters. Clear specs, combiner boxes, isolators, and code-backed sizing for safe selection and fewer outages.

Get a quote

Enabling Smarter DC Link Discharge in EV Traction

Explore the live demonstration of the GD3162''s DC Link discharge feature and discover how NXP is enabling smarter, safer and more efficient

Get a quote

Power resistors & power safety devices for eMobility

EBG DIScharge resistors DIScharge resistors are typically used in the inverter to DIScharge the DC-Link capacitor after driving. The design of our DIScharge resistors varies in the shape,

Get a quote

SLAAEL5 Application brief | TI

This discharge process aims to safeguard occupants or maintenance personnel, minimizing the risk of personal injury from contact with live components or

Get a quote

A DC-Link Hybrid Active Discharge Scheme for Traction Inverters

This paper examines the limitations of traditional discharge techniques and proposes a novel hybrid discharge solution that combines the existing winding-based discharge method with a

Get a quote

Inverter discharges slowly

The attached drawing details DC bus connections (B+/B-) of an inverter drive. When the B- line fuse blows (red arrow), the drive discharges the DC bus (+650Vdc) very

Get a quote

DC-to-DC converter

A DC-to-DC converter is an electronic circuit or electromechanical device that converts a source of direct current (DC) from one voltage level to another. It is a type of electric power converter.

Get a quote

DC Link Discharge

Safe handling of the high-voltage DC link capacitor in an automotive inverter is critical. This capacitor usually requires external discharge circuitry. The GD3162 Advanced IGBT/SiC

Get a quote

Tesla V2L Discharge Device | DC to AC Adapter for

This specialized product is designed to extract DC power directly from Tesla''s fast-charging port and then convert it into safe, usable AC power

Get a quote

1000W Battery Discharge Grid Tie Inverter with

Product Description 1000W Grid Tie Inverter with limiter 24V 48V 72V 96V Battery discharge Solar Panel MPPT Pure Sine Wave Grid Tie Inverter How to

Get a quote

A DC-Link Hybrid Active Discharge Scheme for Traction Inverters

This paper examines the limitations of traditional discharge techniques and proposes a novel hybrid discharge solution that combines the existing winding-based

Get a quote

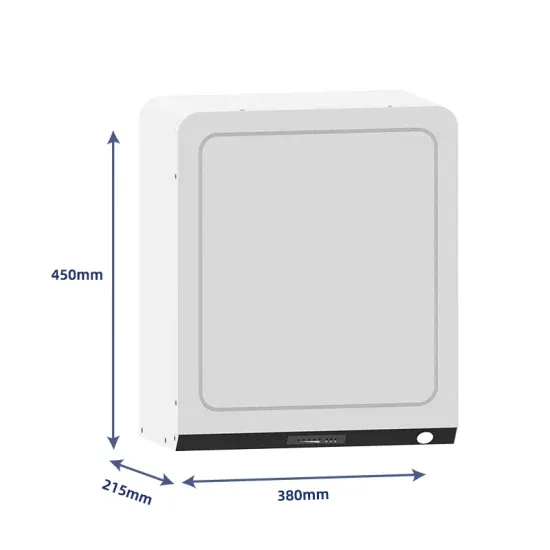

Large Split Side Discharge DC Inverter Series

DC inverter technology, precise temperature control The DC inverter compressor system reaches full load rapidly providing less temperature fluctuation and improved living environment.

Get a quote

RCD Selection for SolarEdge Inverters

Capacitive discharge current - Discharge current is generated mainly by the parasitic capacitance of the PV modules to PE. The module type, the environmental conditions (rain, humidity) and

Get a quote

Tesla V2L Discharger — Vehicle To Load Tech

Once activated, the internal inverter converts the extracted DC current into household AC power, making it suitable for standard appliances. The car

Get a quote

Discharge Circuit Design for DC Bus in Inverters

The schematic of a discharge circuit typically illustrates the connection between the DC bus, discharge resistor, and capacitors. This simple yet effective diagram aids in visualizing current

Get a quote

SMA DC-DC Converter | Intelligently Control the Flow

Intelligently Control the Flow of Power The SMA DC-DC converter allows designers to increase their PV power plant''s yields by oversizing the DC array

Get a quote

Top Discharge VRF JTOH Series

High-Efficiency DC Inverter Scroll Compressor Connection of up to 64 indoor units. Auto Refrigerant Temperature Control (ART). Refrigerant cooled PCB. Independent Maintenance of

Get a quote

6 FAQs about [External discharge DC inverter]

Why do EV inverters need to be discharged?

Abstract: when an Electrical Vehicle (EV) encounters an accident or the vehicle is taken to a service station, the DC-link capacitor in the inverter must be discharged to ensure safety of both the passengers and the operator.

How is power dissipated in an inverter?

The power dissipated by the the inverter’s housi ng or through a cooling s ystem. the current. The discharge energy is used to charge the Low- voltage battery (12 V) us ed as an auxiliary bat tery. the Flyback transformer. A charging current of 1C is used to Ampere ho urs (Ah). The blue trace i n Fig.1 illustrates the energy

What is a DC-link capacitor in a traction inverter?

Figure 1. Simplified Block Diagram of a Traction Inverter The DC-Link capacitor is a part of every traction inverter and is positioned in parallel with the high-voltage battery and the power stage (see Figure 1). The DC-Link capacitor has several functions, such as to help smooth voltage ripples, filtering unwanted harmonics and reducing noise.

How is a DC-link capacitor discharged?

Below the to prevent resurge in voltage on the DC-Link ca pacitor. setup. 920V for both test set ups of concept 1 and 2, usi ng a contactor. link. The capacitor is then discharged through the flyback discharge using either variant 1 or varia nt 2. activation. However, certain applications may require a shorter discharge ti me.

Does a DC-link capacitor have a voltage surge?

This method has no voltage surge, but the discharge time is longer than 5 s. The DC -link due to negative i injection. The proposed hybrid risk of permanent d emagnetization. The i was set in accordance DC -Link capacitor voltage drops below 60 V. With the help of based method with m aximum power discharge. Moreover, the

What happens to DC-link voltage flyback converter during discharge phase?

As a consequence of the DC-link voltage flyback converter’s output power during the discharge phase. is subjected to load c onditions. Fig. 2. Flowchart of d-q current reference implem ented during Discharge. further minimize transi ent power fluctuations. methods initiated at the max imum s peed. The first winding-

Guess what you want to know

-

Solar water pump inverter connected to external power supply

Solar water pump inverter connected to external power supply

-

DC 220V and AC 220V Inverter

DC 220V and AC 220V Inverter

-

Recommendation of DC 300V to 220V inverter

Recommendation of DC 300V to 220V inverter

-

Is there an inverter that can convert DC power to DC

Is there an inverter that can convert DC power to DC

-

Does the inverter have 300v DC

Does the inverter have 300v DC

-

Which brand of 12v DC pure sine wave inverter is good

Which brand of 12v DC pure sine wave inverter is good

-

Photovoltaic DC grid-connected inverter

Photovoltaic DC grid-connected inverter

-

Estonian DC inverter installation

Estonian DC inverter installation

-

DC parallel bidirectional energy storage inverter

DC parallel bidirectional energy storage inverter

-

DC high power inverter price

DC high power inverter price

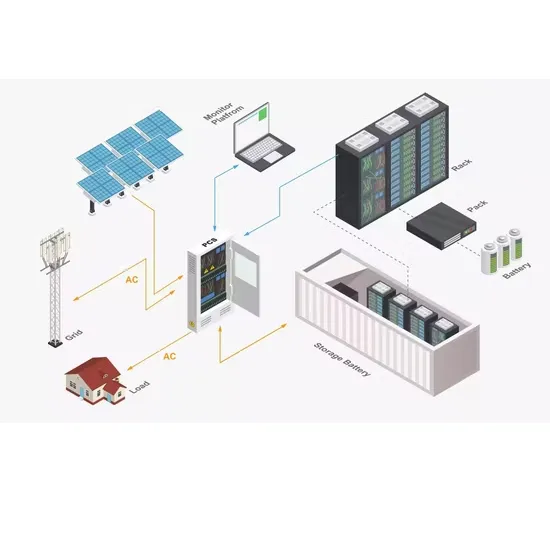

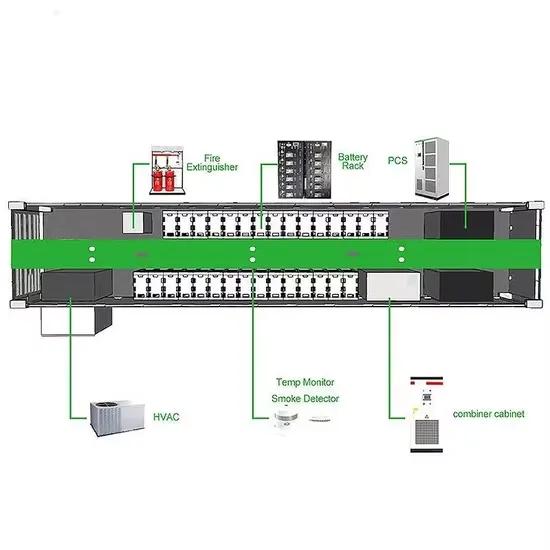

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.