Economics of the Power Industry

Natural Gas Combustion Turbine Generator (CTG) plants have the lowest capital cost at around $974 per Kilowatt, followed by Coal-Fired, Biomass, and Photovoltaic Solar. The most

Get a quote

The cost of electricity — open-electricity-economics 0.1

While the distinction between fixed and variable cost of electricity is important, for various analytical and practical purposes it is often useful to compare the "average cost" of generating

Get a quote

Electricity generation, capacity, and sales in the United States

Terms that are important to understand when learning about electricity production and consumption include: Generation: a measure of electricity produced over time. Most electric

Get a quote

Economics of Power Generation

The semi-fixed cost is directly proportional to the maximum demand on power station and is on account of annual interest and depreciation on capital investment of building and equipment,

Get a quote

Open Electricity Economics: 3. The cost of electricity

Sometimes called the "contribution margin" or "gross profit" of a power plant, this is calculated as the total revenue earned by a power plant minus variable

Get a quote

Five charts on key US electricity and power

U.S. power producers have lifted output from both fossil fuels and clean energy sources to new highs so far in 2025, on the back of steadily

Get a quote

Economics of power generation by a k raja

This will lower the overall cost of the supply of electric energy. Utility Factor It is the ratio of the units of electricity generated per year to the capacity of the plant installed in the station. It can

Get a quote

Cost and Performance Characteristics of New Generating

The costs in Table 1, except as noted below, are the costs for a typical facility for each generating technology before adjusting for regional cost factors. Overnight costs exclude interest accrued

Get a quote

Open Electricity Economics: 3. The cost of electricity

Sometimes called the "contribution margin" or "gross profit" of a power plant, this is calculated as the total revenue earned by a power plant minus variable costs of generation.

Get a quote

Economics of Power Generation

High-cost equipment has higher interest and depreciation charges but lower energy bills. Electrical engineers must balance costs to minimize total plant expenditure.

Get a quote

Power Generation Industry KPIs

Power generation is the business of generating electricity in power plants or power stations, from primary sources of energy. A power plant contains one or

Get a quote

20.1 Electricity generation | Energy and the national

Electricity is generated in a power station. In previous grades, we have looked at how electricity is generated within coal-powered power stations and

Get a quote

Economics of Power Generation

So, power engineers have to find cost-effective methods to provide electricity to customers at affordable prices. While designing or constructing a power station, engineers will

Get a quote

IOWA ELECTRIC GENERATION

Charts 7 and 8, on the following page, offer a comparison of the generation from each fossil power plant over time; it is easy to see both the variability in deployment of fossil resources but also

Get a quote

Valuation of a sequential compound option considering electricity

An integrated model considering both generation and transmission expansions is needed for long-term planning in the electrical sector because of the interlinked nature of these decisions. Our

Get a quote

Revenue for power and utilities companies

For example, a contract to purchase electricity at prices that change each year based on the observable forward market price of electricity would likely qualify for the as-invoiced practical

Get a quote

(PDF) Analysis of short-run and long-run marginal

PDF | In power markets, understanding the cost dynamics of electricity generation is crucial. The complexity of price formation in the power

Get a quote

Utility-scale power generation statistics in South Africa

6 830 10,6 -39% -76% 4 169 2,5 The national average price of electricity increased by 12.74 % percentage this year to reach ~ c/kWh 195 which is much higher than the cost of the latest

Get a quote

Economics of Power Generation: Cost & Depreciation

Explore power generation economics, cost analysis, depreciation methods, and load factor in this textbook chapter. Ideal for engineering students.

Get a quote

The Impact of Interest Rates on Electricity Production Costs

We first estimate the levelized cost of energy (LCOE), which is the price at which electricity must be sold for a plant to break even, for several green and brown energy technologies. We then

Get a quote

2017 Levelized Costs AEO 2012 Early Release

Table 1 represents EIA''s assessment of the cost to develop and install various generating technologies used in the electric power sector. Generating technologies typically found in end

Get a quote

Electricity Generation Costs 2023

Introduction Electricity generation costs are a fundamental part of energy market analysis, and a good understanding of these costs is important when analysing and designing policy to make

Get a quote

The cost of electricity — open-electricity-economics

While the distinction between fixed and variable cost of electricity is important, for various analytical and practical purposes it is often useful to compare the

Get a quote

Economics of Power Generation | SpringerLink

This chapter provides an introduction to the economics of electricity generation, presenting the major economic differences between the multiple power generation solutions

Get a quote

6 FAQs about [The compound interest price of power station electricity generation]

How do you calculate the generation cost of a power station?

If 20% of this expense is also chargeable as fixed charges, calculate the generation cost in two part form. Example 4.10. The annual working cost of a power station is represented by the formula Rs (a + b kW + c kWh) where the various terms have their usual meaning.

What is the rate of interest on a power plant?

The rate of interest depends upon market position and other factors, and may vary from 4% to 8% per annum. Depreciation. The decrease in the value of the power plant equipment and building due to constant use is known as depreciation.

What is the cost structure of electricity generation technologies?

Cost structure of different types of electricity generation technologies (illustrative, but realistic assumptions) Key point: Generation cost certain technologies (wind, solar, nuclear) is almost equal to the fixed costs, while in case of other technologies (coal, gas, etc.) fixed costs make up about half of the total costs.

What is a semi-fixed cost of a power station?

The semi-fixed cost is directly proportional to the maximum demand on power station and is on account of annual interest and depreciation on capital investment of building and equipment, taxes, salaries of management and clerical staff. The maximum demand on the power station determines its size and cost of installation.

What is a capital cost of a power plant?

Interest and depreciation on the capital cost of the generating plant, transmission and distribution network, buildings and other civil engineering works etc. Capital cost of the plant also includes the interest paid during the construction of the plant, salaries of engineers and other employees, development and construction of the power station.

How to calculate annual working cost of a power station?

Annual cost of salaries, maintenance charges etc. is Rs 7,00,000. If 20% of this expense is also chargeable as fixed charges, calculate the generation cost in two part form. Example 4.10. The annual working cost of a power station is represented by the formula Rs (a + b kW + c kWh) where the various terms have their usual meaning.

Guess what you want to know

-

Power station electricity generation price

Power station electricity generation price

-

Energy storage power station electricity price difference

Energy storage power station electricity price difference

-

The latest photovoltaic power station energy storage electricity price standard

The latest photovoltaic power station energy storage electricity price standard

-

How much is the electricity price of the Croatian energy storage power station

How much is the electricity price of the Croatian energy storage power station

-

How much is the electricity price of the Ethiopian power station

How much is the electricity price of the Ethiopian power station

-

Moisture-proof battery cabinet base station power generation

Moisture-proof battery cabinet base station power generation

-

Uzbekistan communication base station wind power and photovoltaic power generation brand

Uzbekistan communication base station wind power and photovoltaic power generation brand

-

Communication base station wind power generation model

Communication base station wind power generation model

-

Zimbabwe 5G base station distributed power generation

Zimbabwe 5G base station distributed power generation

-

Base station power supply wind power generation module

Base station power supply wind power generation module

Industrial & Commercial Energy Storage Market Growth

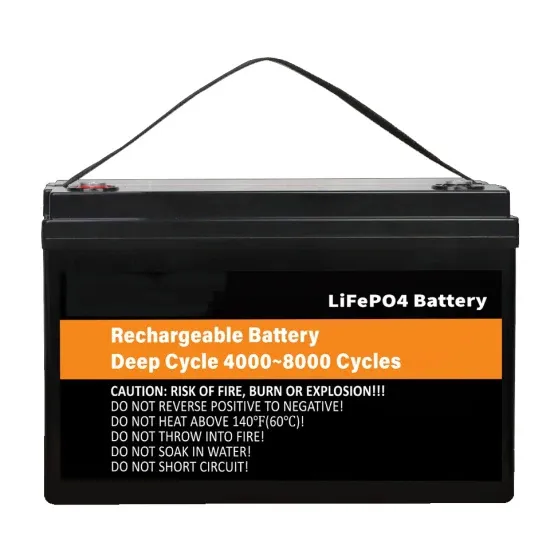

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.