PV Plant Power Flow Modeling Guide

Because of similarities in the internal topology of central station photovoltaic (PV) plants and wind plants, the guidelines contained in this article are very similar

Get a quote

Nanya energy storage power station project

The 150 MW Andasol solar power station is a commercial parabolic trough solar thermal power plant, located in Spain.The Andasol plant uses tanks of molten salt to store captured solar

Get a quote

Nanya energy storage power station

China Southern Power Grid Energy Storage, the energy storage division of China Southern Power Grid, has commissioned a 10 MWh sodium-ion battery storage station in Nanning,

Get a quote

China''s Photovoltaic Power Stations from Space--Aerospace

Located within the Tengger Desert in northwestern China, covering an area of 43 square kilometers with a generation capacity of 1,500 MW, it combines PV generation with

Get a quote

Photovoltaic Power Generation Model and its Analysis Based on

Based on real-time data collected from a specific photovoltaic power plant, mathematical modeling of the electricity output of the photovoltaic power plant is f

Get a quote

anantgupta129/Solar-Power-Generation-Forecasting

We want to predict the power output for a particular array of solar power generators, knowing some environmental conditions. Solar power forecasting is very usefull in smooth operation

Get a quote

anantgupta129/Solar-Power-Generation-Forecasting

We want to predict the power output for a particular array of solar power generators, knowing some environmental conditions. Solar power forecasting

Get a quote

Forecasting of photovoltaic power generation and model

A significant number of historical time series data of PV power output and corresponding meteorological variables are used to establish the forecasting model of PV

Get a quote

Solar Photovoltaic Power Plant Modeling and Validation

This document examines the representation of BPS-connected solar PV plants in both power flow and dynamic data sets for BPS studies. The document outlines modeling

Get a quote

Energy Power Station Solar Panel PV Array Rack Battery Bank 3D Model

The array serves as the primary energy harvesting component of the power station, converting solar irradiance into usable electrical energy.

Get a quote

Solar Photovoltaic Power Plant Modeling and Validation

The REMTF recommends that each central station solar PV plant (aggregated capacity ≥ 20 MVA and connected to 60 kV and above) is modeled explicitly in the power flow

Get a quote

Frontiers | Modeling of Photovoltaic Power Generation

The photovoltaic power station has a good development prospect because it can realize concentrated and efficient utilization of solar energy.

Get a quote

Frontiers | Modeling of Photovoltaic Power Generation

To solve this problem, this study proposes a simplified model, average model, which uses a controlled current source to replace the power

Get a quote

Solar Power Station

The largest CSP systems using PTC technology include, the 354 MW Solar Energy Generating Systems (SEGS) plants in California, the 280 MW Solana Generating Station that features a

Get a quote

User Guide for PV Dynamic Model Simulation Written on

Section 3 presents the control implementation of a PV inverter and a PV plant. The Renewable Energy Modeling Task Force (REMTF) of the Western Electricity Coordinating Council

Get a quote

China Petroleum launches first perovskite photovoltaic

1 day ago· According to reports, PetroChina Shenzhen New Energy Research Institute has completed the group''s first perovskite module PV demonstration power station at Well Xian

Get a quote

nanya energy storage power station

Nanya Cogen power station has a peak capacity of 148.0 MW which is generated by Coal. The power plant was commissioned in 2004 and started energy production the same year.

Get a quote

Solar Power Plants: Types, Components and Working Principles

The layout of a photovoltaic power plant depends on several factors, such as site conditions, system size, design objectives, and grid requirements. However, a typical layout

Get a quote

New models of solar photovoltaic power generation efficiency

In this study, a solar photovoltaic power generation efficiency model based on spectrally responsive bands is proposed to correct the solar radiation received by the PV

Get a quote

Stacking Model for Photovoltaic-Power-Generation

Despite the clean and renewable advantages of solar energy, the instability of photovoltaic power generation limits its wide applicability. In order

Get a quote

PV Plant Power Flow Modeling Guide

Because of similarities in the internal topology of central station photovoltaic (PV) plants and wind plants, the guidelines contained in this article are very similar to a previously issued guide for

Get a quote

Equivalent Model of Photovoltaic Power Station Considering

Abstract: The fault current calculation model of photovoltaic (PV) power stations is usually treated as a capacity weighted equivalent model of a single PV generation unit (PVGU).

Get a quote

PV Plant Power Flow Modeling Guide

PV Plant Power Flow Modeling Guide Author: WECC REMTF [1] A large amount of PV generation is projected to be installed in the Western Interconnection in

Get a quote

(PDF) Research on prediction method of photovoltaic

To improve the prediction accuracy of photovoltaic power, a photovoltaic power generation prediction machine learning model based on

Get a quote

Nanya energy storage project factory operation

Scientist | R& D Project Manager | Grid Operations | Siemens Technology · An experienced Power System Consultant, currently working as an R& D project manger in the filed of

Get a quote

Frontiers | Modeling of Photovoltaic Power Generation Systems

To solve this problem, this study proposes a simplified model, average model, which uses a controlled current source to replace the power electronic converter and analyzes

Get a quote

6 FAQs about [Nanya Photovoltaic Power Station Power Generation Model]

What is a dynamic model for a central station solar PV plant?

The dynamic model for a central station solar PV plant includes 2 or 3 modules and has between 45 and 75 unique parameters, depending on whether a plant controller is in place. The resulting model has a high degree of flexibility and can be configured in over 30 unique modes of operation.

What dynamic models are used for solar PV plants?

WECC approved the use of two generic dynamic models for solar PV plants: (a) a model consisting of plant controller, electrical controls, and grid interface modules intended for large-scale solar PV plants; and (b) a simplified model intended for distribution-connected, aggregated solar PV plants.

Are central-station photovoltaic (PV) plants similar to wind power plants?

Because of similarities in the internal topology of central station photovoltaic (PV) plants and wind plants, the guidelines contained in this article are very similar to a previously issued guide for wind power plants. REMTF recommends the use of the single-machine equivalent representation to model central-station PV plants in WECC base cases.

How is forecasting model of PV power generation based on historical data?

A significant number of historical time series data of PV power output and corresponding meteorological variables are used to establish the forecasting model of PV power generation. The historical series data are divided in two groups: the training and testing data.

Can a PV plant be modeled at full output?

In the context of an interconnection study, a PV plant would be modeled at full output. For other studies, PV plants may be modeled at partial output or zero output. For instance, WECC off-peak cases correspond to nigh-time periods, when PV output is zero.

What types of data are useful for model validation of solar PV plants?

The types of data useful for model validation of solar PV plants can be divided into two categories. The first corresponds to the system’s response to repeatable tests, and the second corresponds to the system’s response to spontaneously occurring disturbances.

Guess what you want to know

-

Voltage at the power generation end of the photovoltaic power station

Voltage at the power generation end of the photovoltaic power station

-

Central African Republic communication base station wind power and photovoltaic power generation quotation

Central African Republic communication base station wind power and photovoltaic power generation quotation

-

Photovoltaic power station power generation in Portugal

Photovoltaic power station power generation in Portugal

-

Chad communication base station grid-connected photovoltaic power generation

Chad communication base station grid-connected photovoltaic power generation

-

Libya communication base station photovoltaic power generation parameters

Libya communication base station photovoltaic power generation parameters

-

Peru 5G base station photovoltaic power generation system energy storage

Peru 5G base station photovoltaic power generation system energy storage

-

Abkhazia emergency communication base station photovoltaic power generation system

Abkhazia emergency communication base station photovoltaic power generation system

-

5g network circuit base station photovoltaic power generation system

5g network circuit base station photovoltaic power generation system

-

Base station power photovoltaic power generation equipment

Base station power photovoltaic power generation equipment

-

48v communication base station photovoltaic power generation

48v communication base station photovoltaic power generation

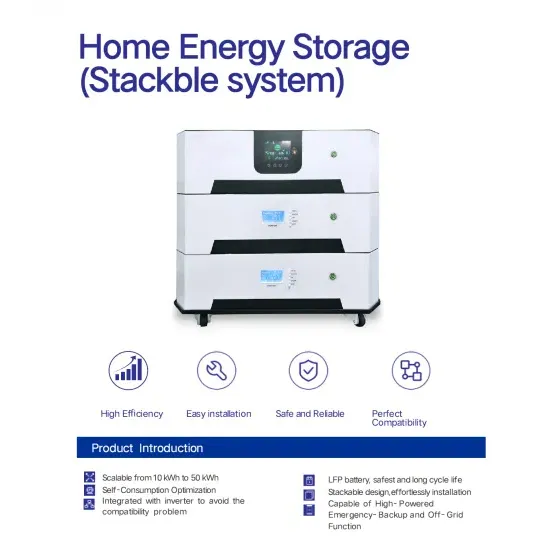

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.