Causes and preventive measures for overvoltage generated by

There are two main causes of overvoltage: power supply overvoltage and regenerative overvoltage. The overvoltage of the power supply means that the DC bus voltage

Get a quote

Managing VFD Overvoltage Faults During Deceleration

During deceleration of a high-inertia load, the motor (right) can generate power back into the DC link. A brake chopper transistor (DB+ to DB–) diverts excess energy into the braking resistor

Get a quote

Dc-link capacitor voltage control for the NPC three-level inverter

Abstract Dc-link capacitor voltage unbalance would affect the performance of the neutral-point clamped (NPC) three-level inverter. With the traditional virtual space vector

Get a quote

Reinforced Isolation 3-Phase Inverter With Current Voltage

The inverter is designed to protect against overload, short circuit, ground fault, DC bus undervoltage and overvoltage, and IGBT module over-temperature. The DC bus voltage is

Get a quote

Comparison of DC-link Voltage Balancing Strategies for Three Level

A major drawback of three-level neutral point clamped (NPC) inverters is the imbalance in the DC-link voltage. The unbalanced capacitor voltage fluctuates the neutral point voltage and causes

Get a quote

Inverter reports overvoltage error – Causes and instructions

The common cause of the inverter''s overvoltage is the voltage on the DC bus being too high, beyond the allowable threshold of the inverter. So what causes high voltage on DC bus?

Get a quote

A systematic design methodology for DC-link voltage control of

The first stage is based on a DC/DC boost converter that is controlled with an MPPT algorithm [14] in order to extract as much power as possible from the PV panels. The

Get a quote

Minimization of DC-Link Ripple Current for Enhancing Reliability

This paper proposes a DC-link ripple current minimization strategy to enhance the reliability of three-level voltage source inverters (3L-VSIs). The largest current among the three

Get a quote

What is the cause of the overvoltage of the inverter? How to

From this article, you will get the answer for that what is the cause of the overvoltage of the inverter and how to prevent it.

Get a quote

How to Troubleshoot AC Overvoltage of Solar Inverter?

2. Overvoltage caused by wrong connection of AC wire If the AC wire of the solar inverter is connected in a wrong way, the AC voltage overrange failure may be caused. If the

Get a quote

An advanced guide to Understanding DC to AC inverters

Yes! Knowing the difference will help you understand energy efficiency better and may even save you some money. Understanding the concept also allows you to recognize the

Get a quote

DC Bus Overvoltage White Paper

The DC bus overvoltage fault is typically an application error resulting from one of three conditions or a combination. These conditions are a high line voltage, the motor being back-driven by a

Get a quote

ANALYSIS OF TWO LEVEL AND THREE LEVEL INVERTERS

The inverters which produce which produce an output voltage or a current with levels either 0 or +-V are known as two level inverters. In high-power and high-voltage applications these two

Get a quote

Causes of DC overvoltage in photovoltaic inverters

Scientists at the University of South Australia have identified a series of strategies that can be implemented to prevent solar power losseswhen overvoltage-induced inverter disconnections

Get a quote

Natural DC-link voltage balance in a single-phase

For the three-level NPC inverter with a natural balancing ability, the relatively simple carrier-based switching strategy can be used. Natural DC-link

Get a quote

analytical

The DC link capacitor is an important component in a three-level inverter. Selection of appropriate DC link capacitor is a critical step in the design of a three-level inverter [2].

Get a quote

DC offset minimisation of three-phase multilevel

To address this problem, a five-level inverter is proposed which is capable of energy balancing between the two DC sources, minimising the DC

Get a quote

Analysis and treatment of inverter DC overvoltage fault

The main causes of inverter DC overvoltage faults are overvoltage caused by the power input side, overvoltage caused by the load side, and overvoltage caused by internal damage of the

Get a quote

Causes and preventive measures for overvoltage generated by the inverter

There are two main causes of overvoltage: power supply overvoltage and regenerative overvoltage. The overvoltage of the power supply means that the DC bus voltage

Get a quote

Inverter reports overvoltage error – Causes and

The common cause of the inverter''s overvoltage is the voltage on the DC bus being too high, beyond the allowable threshold of the inverter. So what causes

Get a quote

Strategies to prevent overvoltage-induced inverter

Australian scientists have identified seven methods to prevent PV losses when overvoltage-induced inverter disconnections occur. The methods

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage. This is caused by a high intermediate circuit DC voltage. This

Get a quote

Inverter Ground Fault Overvoltage Testing

We also present brief investigations into the effects of changing inverter overvoltage and overfrequency trip settings, the effect of anti-islanding controls, and the effect of delta- and wye

Get a quote

Guess what you want to know

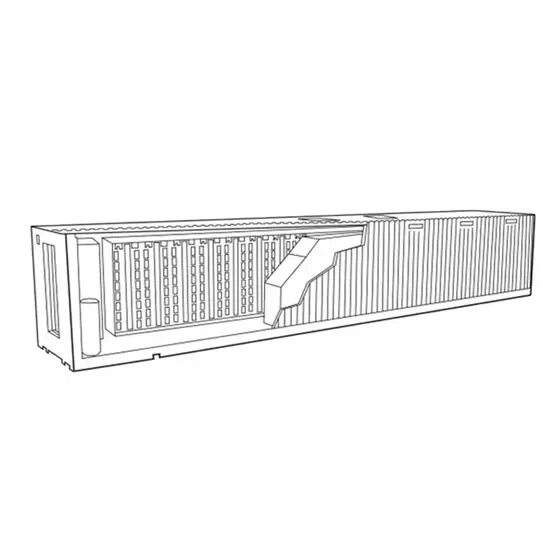

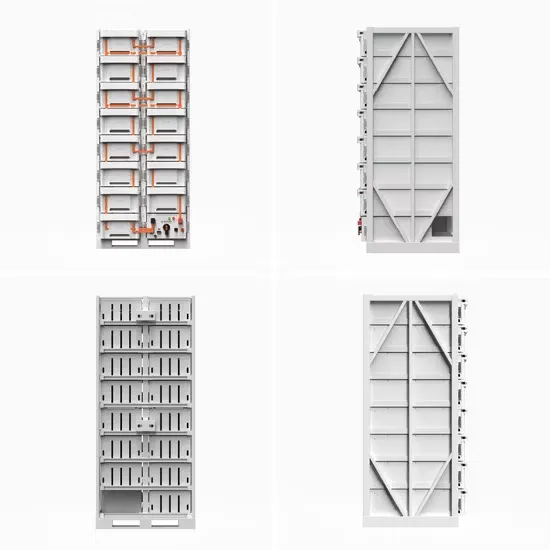

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.

Lithuania DC power inverter

Lithuania DC power inverter

Eritrea DC Solar PV Water Pump Inverter

Eritrea DC Solar PV Water Pump Inverter

High-voltage DC to AC inverter

High-voltage DC to AC inverter

Inverter DC 36V output

Inverter DC 36V output

Inverter DC maximum voltage

Inverter DC maximum voltage

310v DC inverter

310v DC inverter

220v DC power inverter

220v DC power inverter

24V Solar DC Inverter

24V Solar DC Inverter

Mauritania inverter DC voltage wholesale

Mauritania inverter DC voltage wholesale

Photovoltaic 550 DC Inverter

Photovoltaic 550 DC Inverter