Flywheel energy storage systems: A critical review on

Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Get a quote

A review of flywheel energy storage systems: state of the art

A rotor with lower density and high tensile strength will have higher specific energy (energy per mass), while energy density (energy per volume) is not affected by the material''s

Get a quote

China connects its first large-scale flywheel storage project to grid

The 30 MW plant is the first utility-scale, grid-connected flywheel energy storage project in China and the largest one in the world.

Get a quote

FESS Fkywheel Energy Storage Systems

The rate at which energy can be stored or discharged from a flywheel energy storage system depends on the design of the system, including the mass and

Get a quote

Flywheel Energy Storage Systems | Electricity

Flywheel technology is a method of energy storage that uses the principles of rotational kinetic energy. A flywheel is a mechanical device that stores energy

Get a quote

The Status and Future of Flywheel Energy Storage

2 (Equation 1) where E is the stored kinetic energy, I is the flywheel moment of inertia [kgm2], and is the angular speed [rad/s]. In or-der to facilitate storage and extraction of electrical energy,

Get a quote

Microsoft Word

In this paper, we present a procedure of obtaining an accurate rotor model of a large flywheel energy storage system using finite-element method. The system is designed to store 5kWh at

Get a quote

Flywheel Energy Storage Systems | Electricity Storage Units

A flywheel is a mechanical device that stores energy by spinning a rotor at very high speeds. The basic concept involves converting electrical energy into rotational energy, storing it, and then

Get a quote

Energy Storage Flywheel Rotors—Mechanical Design

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in

Get a quote

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get a quote

Flywheel

A mass-produced flywheel The kinetic energy (or more specifically rotational energy) stored by the flywheel''s rotor can be calculated by . ω is the angular velocity, and is the moment of

Get a quote

Flywheel energy storage—An upswing technology for energy

Flywheel energy storage (FES) can have energy fed in the rotational mass of a flywheel, store it as kinetic energy, and release out upon demand. It is a significant and

Get a quote

DOE ESHB Chapter 7 Flywheels

In this application, the speed of the flywheel varies only slightly between pulses and relatively little energy is stored in the rotor. For example, the massive rotor of the Corliss Centennial Engine

Get a quote

What is a flywheel?

Speed vs. Mass Key performance indices of a flywheel rotor are the spinning speed and the mass. The total energy stored in a flywheel scales linear to the mass and quadratically to the

Get a quote

FESS Fkywheel Energy Storage Systems

The rate at which energy can be stored or discharged from a flywheel energy storage system depends on the design of the system, including the mass and shape of the rotor, the speed at

Get a quote

Flywheel Energy Storage

Flywheel energy storage is a form of mechanical energy storage that works by spinning a rotor (flywheel) at very high speeds. This stored energy can be quickly converted back to electricity

Get a quote

A review of flywheel energy storage rotor materials and structures

This article introduces the evaluation indicators of flywheel rotor. The material characteristics of metal flywheel rotor and composite flywheel rotor are introduced. The

Get a quote

The role of flywheel energy storage in decarbonised

The minimum speed of the flywheel is typically half its full speed, the storage energy is be given by ½ (12-0.52) Ifwf2 where If is the rotor moment of inertia

Get a quote

DOE ESHB Chapter 7 Flywheels

Over the past 50 years of the development of flywheel energy storage systems, numerous unusual configurations have been explored. These include straight fibers oriented along the

Get a quote

Energy Storage Flywheel Rotors—Mechanical Design

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in mechanical energy and vice

Get a quote

A review of flywheel energy storage rotor materials and structures

The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Get a quote

Strength Analysis of Carbon Fiber Composite Flywheel Energy Storage

The dimensions of the flywheel energy storage device for power frequency regulation using carbon fiber composite materials, as described in reference [24], simplify the

Get a quote

Rotor Design for High-Speed Flywheel Energy Storage Systems

The disk-shaped flywheel rotor was made of steel, had a mass of about 1.5 metric tons and reached a maximum angular velocity of 314 rad/s or 3000 rounds per minute (rpm). In regular

Get a quote

How Flywheel Energy Storage is Stabilizing Power

Flywheel energy storage systems have recently been found to be one of the firmest and most reliable solutions to stabilize power grids, primarily

Get a quote

Flywheel Energy Storage: The Spinning Marvel of Modern Power

At its core, flywheel energy storage converts electrical energy into rotational kinetic energy. Think of it like revving up a toy car''s wheels—except here, the "wheel" is a massive

Get a quote

Guess what you want to know

-

How big is the largest energy storage battery cabinet

How big is the largest energy storage battery cabinet

-

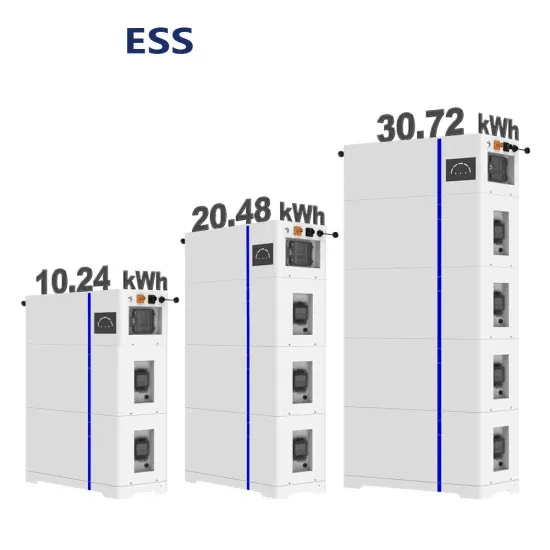

How big is the capacity of the energy storage battery

How big is the capacity of the energy storage battery

-

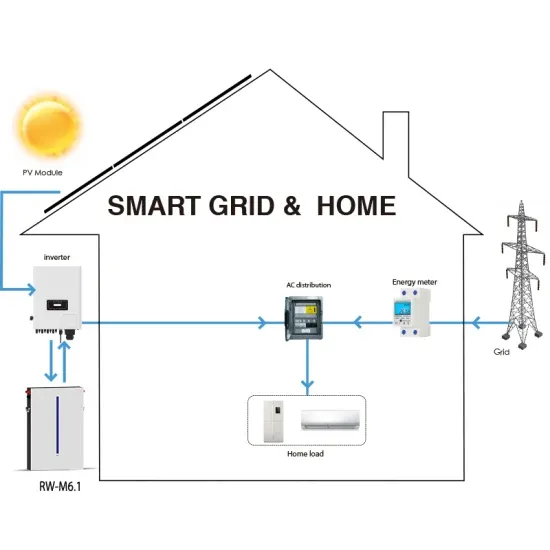

How big should household energy storage batteries be

How big should household energy storage batteries be

-

How much does 1 MW of flywheel energy storage cost

How much does 1 MW of flywheel energy storage cost

-

How big a battery should a 2MW energy storage system be

How big a battery should a 2MW energy storage system be

-

How big is the lead-acid battery for energy storage

How big is the lead-acid battery for energy storage

-

How big does the energy storage cabinet at a charging station need to be

How big does the energy storage cabinet at a charging station need to be

-

How big are the batteries used in energy storage containers

How big are the batteries used in energy storage containers

-

Flywheel energy storage rotor processing

Flywheel energy storage rotor processing

-

How big is Venezuela s energy storage power station

How big is Venezuela s energy storage power station

Industrial & Commercial Energy Storage Market Growth

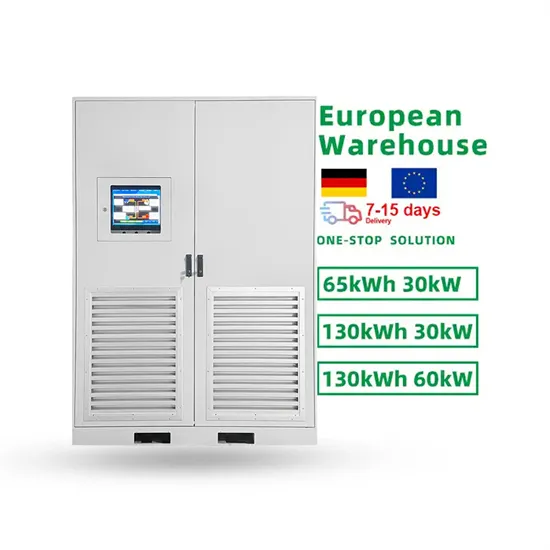

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.