Thin-Film Solar Technology (2025) | 8MSolar

Instead of using thick layers of crystalline silicon, thin-film solar cells are made by depositing one or more thin layers of photovoltaic material

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros & Cons

The most commonly used ones for thin-film solar technology are cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous silicon (a-Si), and gallium

Get a quote

Thin-Film Solar Technology (2025) | 8MSolar

Instead of using thick layers of crystalline silicon, thin-film solar cells are made by depositing one or more thin layers of photovoltaic material onto a substrate. These layers are

Get a quote

Thin-Film Solar Cells: Definition, Types & Costs

Thin-film solar cells are a type of photovoltaic device that converts sunlight into electricity using layers of semiconductor materials applied thinly

Get a quote

Forget about standard solar panels: thin films are coming

A technological transition has started in the solar panel market, with crystalline silicon panels witnessing the advent of promising thin-film

Get a quote

Ultra-Thin Solar Cells Development: The Next Shift in

Learn the ins and outs of ultra-thin solar cells development, including their advantages, efficiency, flexibility, and potential future

Get a quote

Advanced Thin-Film Solar Panel Manufacturing: How

Material deposition technologies play a crucial role in thin-film solar panel manufacturing, determining the quality, efficiency, and cost

Get a quote

Thin-film Solar Overview | Cost, types, application, efficiency

Thin-film solar cells provide more efficient ways to generate electricity from sunlight than any other solar cells. It is comprise of amorphous solar cells and are

Get a quote

How Thin-Film Solar Panels Are Transforming the Renewable

Thin-film solar panels are transforming the renewable energy sector with their unique blend of flexibility, cost-effectiveness, and performance in diverse conditions. From urban landscapes

Get a quote

18 Times More Power: MIT Researchers Have Developed

Six years ago, the ONE Lab team produced solar cells using an emerging class of thin-film materials that were so lightweight they could sit on top of a soap bubble. But these

Get a quote

MIT''s new ultra-thin solar cells can turn almost any surface into a

MIT''s new solar cells are lighter and thinner and can be laminated onto almost any surface. MIT researchers have developed a scalable fabrication technique to produce ultrathin,

Get a quote

Thin-film solar cell

OverviewHistoryTheory of operationMaterialsEfficienciesProduction, cost and marketDurability and lifetimeEnvironmental and health impact

Thin-film solar cells are a type of solar cell made by depositing one or more thin layers (thin films or TFs) of photovoltaic material onto a substrate, such as glass, plastic or metal. Thin-film solar cells are typically a few nanometers (nm) to a few microns (μm) thick–much thinner than the wafers used in conventional crystalline silicon (c-Si) based solar cells, which can be up to 200 μm thick. Thi

Get a quote

Paper-thin solar cell can turn any surface into a power source

MIT researchers have developed a scalable fabrication technique to produce ultrathin, lightweight solar cells that can be stuck onto any surface. The thin-film solar cells

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types,

The most commonly used ones for thin-film solar technology are cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous

Get a quote

Solar PV Manufacturing Basics Explained

Solar photovoltaic (PV) manufacturing is the foundation of today''s clean energy revolution. From PV module manufacturing to racking systems and power electronics, each

Get a quote

Thin-film solar cell

Thin-film solar cells are a type of solar cell made by depositing one or more thin layers (thin films or TFs) of photovoltaic material onto a substrate, such as glass, plastic or metal.

Get a quote

MIT makes a super thin solar cell that can turn any surface into a

MIT engineers have unveiled a groundbreaking achievement in solar technology with the creation of ultralight fabric solar cells. These cells, thinner than a human hair and just one-hundredth the...

Get a quote

18 Times More Power: MIT Researchers Have

Six years ago, the ONE Lab team produced solar cells using an emerging class of thin-film materials that were so lightweight they could sit on

Get a quote

Revolutionary ultra-thin solar cells poised to change energy

Recent advancements in solar technology have introduced a groundbreaking development: solar cells that are 50 times thinner than a human hair and 25 times lighter than

Get a quote

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting,

Get a quote

Efficiency of Thin Film Solar Panels: A Comprehensive Guide for

Gain insights into efficiency of thin film solar panels. Explore our comprehensive guide for optimal energy use, performance, & sustainable living.

Get a quote

MIT''s new ultra-thin solar cells can turn almost any

MIT''s new solar cells are lighter and thinner and can be laminated onto almost any surface. MIT researchers have developed a scalable

Get a quote

Thin Film Solar Panels in 2025: Efficiency, Types & Cost | Utec by

The Rise of Thin Film Solar Technology As solar energy adoption accelerates in 2025, a new generation of panels is gaining momentum: thin film solar panels. Known for their

Get a quote

Ultra-Thin Solar Cells Development: The Next Shift in Solar Energy

Learn the ins and outs of ultra-thin solar cells development, including their advantages, efficiency, flexibility, and potential future breakthroughs.

Get a quote

Scientists create ultra-thin solar panels that are 1,000x

Scientists have unlocked a new way to make solar panels far more efficient—up to 1,000 times better than current methods. The team at a

Get a quote

Advanced Thin-Film Solar Panel Manufacturing: How Modern

Material deposition technologies play a crucial role in thin-film solar panel manufacturing, determining the quality, efficiency, and cost-effectiveness of the final product.

Get a quote

Guess what you want to know

-

One-watt solar panel production

One-watt solar panel production

-

Solar panel factory production equipment installation

Solar panel factory production equipment installation

-

Solar panel 2mm production plant

Solar panel 2mm production plant

-

Subsidies for solar panel production

Subsidies for solar panel production

-

Solar panel production inverter

Solar panel production inverter

-

Congo solar panel production plant

Congo solar panel production plant

-

Photovoltaic automation solar panel production

Photovoltaic automation solar panel production

-

Solar panel curtain wall production

Solar panel curtain wall production

-

Solar photovoltaic panel production in Mexico

Solar photovoltaic panel production in Mexico

-

Burkina Faso solar photovoltaic panel production equipment

Burkina Faso solar photovoltaic panel production equipment

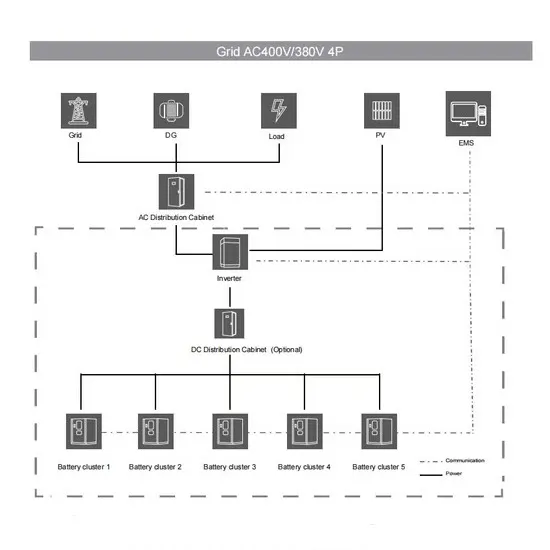

Industrial & Commercial Energy Storage Market Growth

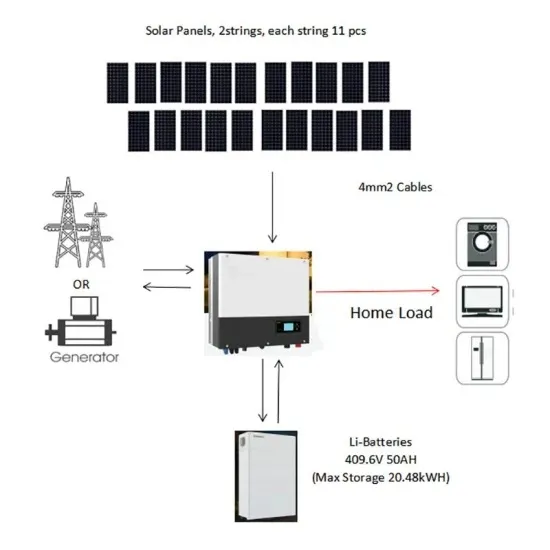

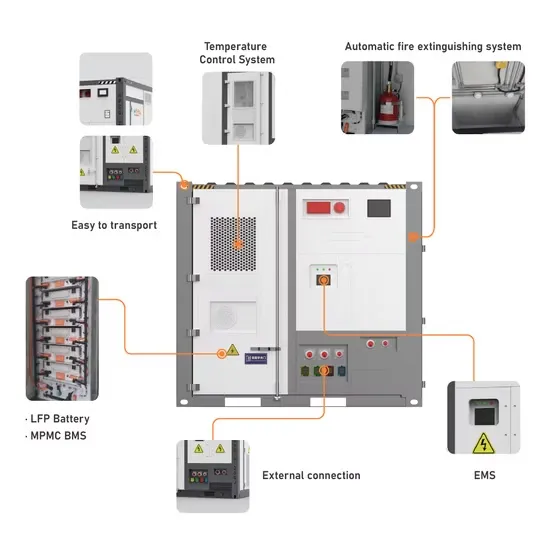

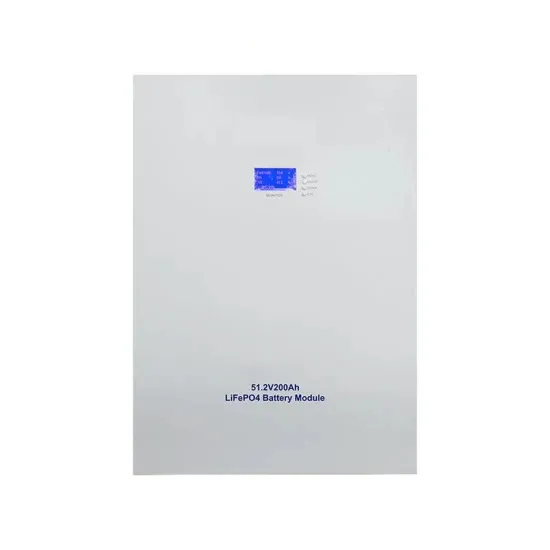

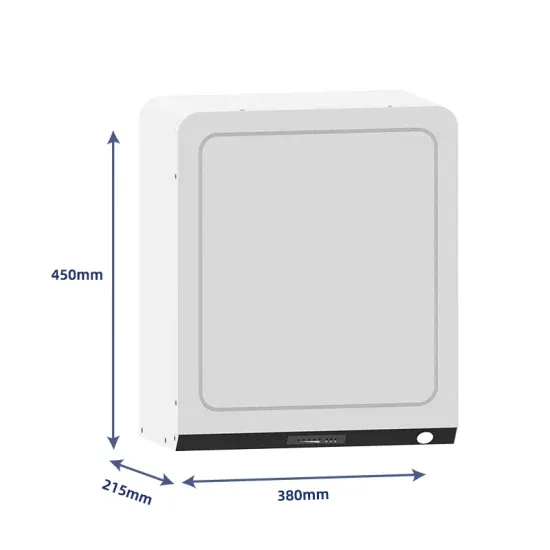

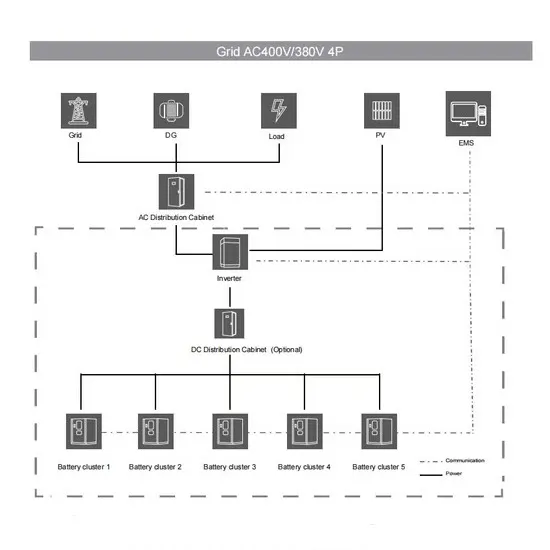

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.