Standardizing a new paradigm in base station architecture

New antenna-integrated base station architectures were emerging and looking forward, an exciting breakthrough in the feasibility of using millimetre wave technologies was

Get a quote

Seismic fragility analysis of critical facilities in communication base

The seismic fragility analysis of communication equipment can be utilized for pre-earthquake disaster prediction and targeted improvement of their seismic performance; on the

Get a quote

Microsoft PowerPoint

These are the important factors in ground station design. The spacecraft orbit and mission characteristics will drive available locations for ground systems. Satellite transmitter

Get a quote

Flexible graphite base grounding body and its application in

Compared with the traditional grounding body,the Shi Moji flexible grounding body had low grounding resistance and stable structure under the high and low temperature cycle can

Get a quote

Electrical Grounding For Telecommunications Systems

This course will address electrical and mechanical grounding in central offices, loop access sites like DLCs, buildings, and wireless communications installations such as base station sites and

Get a quote

Introduction to Satellite Ground Stations

Satellite ground stations serve as the vital link between satellites orbiting in space and Earth-based systems, ensuring the uninterrupted flow of

Get a quote

Aerial base station

An Aerial base station (ABS), also known as unmanned aerial vehicle (UAV)-mounted base station (BS), is a flying antenna system that works as a hub between the backhaul network

Get a quote

Guide to the Canadian Electrical Code, Part I: Section 36

Rule 36- 308 Connections to the Station Ground Electrode — requires that all non-current carrying metal equipment and structures forming

Get a quote

Distribution Operations Overview of Organization, Systems

J-Bolt (metal) used to anchor JPS 220V line to wood pole. Standard and safe Practice. Insulators used to anchor JPS 220V line to pole. Transmission Ops. EOC. Clearing the streets of

Get a quote

Mobile Communication Base Station & Microwave

It is extremely difficult to make the grounding resistance small and meet the requirements. Therefore, rational design of grounding systems for

Get a quote

Cell Tower Grounding: Safety & Compliance Solutions

With proper soil resistivity testing however, we can provide communication tower grounding solutions that will achieve 5 ohm resistance to ground and meet the

Get a quote

Station Ground

The station entrance panel ground must ground all cable grounds as they enter, including power mains and telco grounds. Everything has to be at the same potential entering the room.

Get a quote

Mobile Communication Base Station & Microwave Station Grounding

It is extremely difficult to make the grounding resistance small and meet the requirements. Therefore, rational design of grounding systems for various mobile

Get a quote

Cell Tower Grounding: Safety & Compliance Solutions

With proper soil resistivity testing however, we can provide communication tower grounding solutions that will achieve 5 ohm resistance to ground and meet the stringent requirements

Get a quote

Effective Communication Tower Grounding Design

The solution is a properly engineered grounding system that can successfully dissipate energy surges while mitigating the risk to equipment in order to minimize downtime.

Get a quote

Communication Base Station Grounding System | HuiJue Group

Did you know that 68% of base station failures originate from inadequate grounding? As telecom operators worldwide scramble to deploy 5G networks, the communication base station

Get a quote

Work from the Ground UP

The goal of a good RF ground system is to obtain as "little" resistance as possible between the "antenna/tower-to-ground" and the "radio-to-ground". Thus the more conductive surface area

Get a quote

ETCR2900 Online Earth Resistance Tester,online ground resistance

ETCR2900 Contact Type On-line Earth Resistance Tester suitable for transmission line tower grounding, underground mine equipment grounding, weather lightning protection

Get a quote

What Is a Good Ground Resistance Value?

The goal in ground resistance (or earth resistance) is to achieve the lowest ground resistance value possible, that makes sense economically and physically, when contacting the

Get a quote

Communication Base Station Lightning Arrestor | HuiJue Group E

Here''s the kicker: Tower grounding resistance below 5 ohms (per IEC 62305) could actually increase equipment stress during fast-rising surges. Our field measurements in Brazil showed

Get a quote

Effective Communication Tower Grounding Design

The solution is a properly engineered grounding system that can successfully dissipate energy surges while mitigating the risk to equipment in

Get a quote

Telecommunications Grounding and Bonding | nVent

Over 25 courses available for telecommunication, including many specialized grounding and bonding topics; Indoor Grounding System Design at a Telecommunications Facility – Codes

Get a quote

Grounding and Bonding For Home Stations

EVERYTHING IN THE STATION IS AN ANTENNA! A single, solid ground system made of short, heavy, direct connections can satisfy all of the requirements for... Block, R. R., The "Grounds"

Get a quote

Where Grounding Bonds with Science®

Copper wire communications cables within high voltage environments such as substations, power plants and transmission tow-ers, can be exposed to thousands of volts during a power system

Get a quote

6 FAQs about [Jamaica Communication Base Station Ground Resistance]

What is a good grounding electrode resistance for a communication tower?

According to the IEEE Std 142-1991 and IEEE Std 142-2007 (The Green Book), the communication tower grounding electrode resistance of large electrical substations should be 1 Ohm resistance or less. For commercial and industrial substations including cell site and telecommunications sites the recommended resistance to ground is 5 Ohms or less.

What are the standards for cell site grounding & telecommunications tower grounding?

Our cell site grounding,telecommunications grounding and communication tower grounding methods closely follow the Motorola R56 standards and IEEE Std 142-1991 and IEEE Std 142-2007 recommended Practice for Grounding of Industrial and Commercial Power Systems guidelines for cell site and telecommunications sites.

Who provides cell site grounding & telecommunication tower grounding services?

The experts at E&S Grounding Solutions provide comprehensive cell site grounding and telecommunication grounding solutions for Cell Site grounding or BTS Cellular Base Station grounding. Our cell site grounding and telecommunication tower grounding services protect your valuable equipment!

What Ohm Resistance should a substation have?

For commercial and industrial substations including cell site and telecommunications sites the recommended resistance to ground is 5 Ohms or less. This low resistance is required due to the high potential to earth of the electrical system.

What is a house station internal common point ground?

A house station's internal common point ground is the single point where transmitting cables go to connect to an 8-position relay cross-over antenna switch and harmonic suppression filters. This switch routes cables and allows any tower's grouped feed line or single antenna feed line to be connected to any radio.

How much ground resistance does a substation need?

Typically, the subterranean grid system of a substation will give the needed resistance. 5Ω is frequently the acceptable value in light industrial or telecommunication central offices. For lightning protection, the arrestors must be paired with a maximum ground resistance of 1Ω.

Guess what you want to know

-

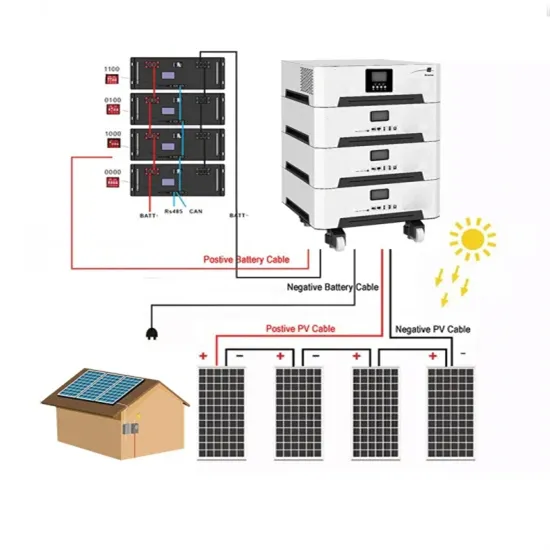

Jamaica Communication Base Station Wind and Solar Hybrid Energy Storage Cabinet Company

Jamaica Communication Base Station Wind and Solar Hybrid Energy Storage Cabinet Company

-

Ground photovoltaic communication base station power supply

Ground photovoltaic communication base station power supply

-

Ground auxiliary base station emergency communication

Ground auxiliary base station emergency communication

-

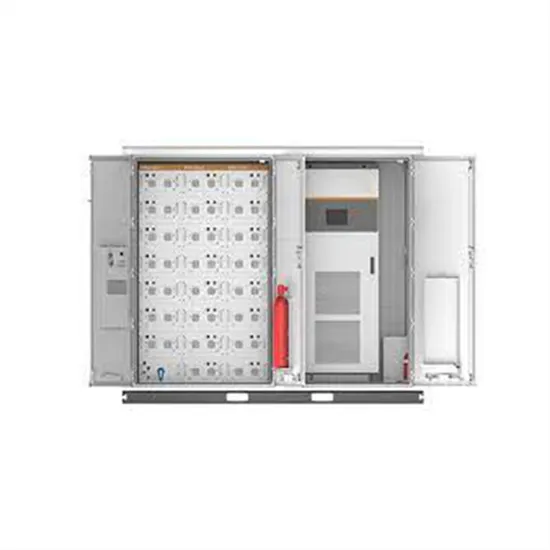

Construction of energy storage system for ground wave communication base station

Construction of energy storage system for ground wave communication base station

-

What is the maximum battery discharge capacity of a communication base station

What is the maximum battery discharge capacity of a communication base station

-

How to replace the wind power battery of the communication base station

How to replace the wind power battery of the communication base station

-

Morocco communication base station lead-acid battery bidding

Morocco communication base station lead-acid battery bidding

-

How much is a communication base station battery worth

How much is a communication base station battery worth

-

Intelligent network communication base station wind and solar complementary

Intelligent network communication base station wind and solar complementary

-

Base station communication power generation power density

Base station communication power generation power density

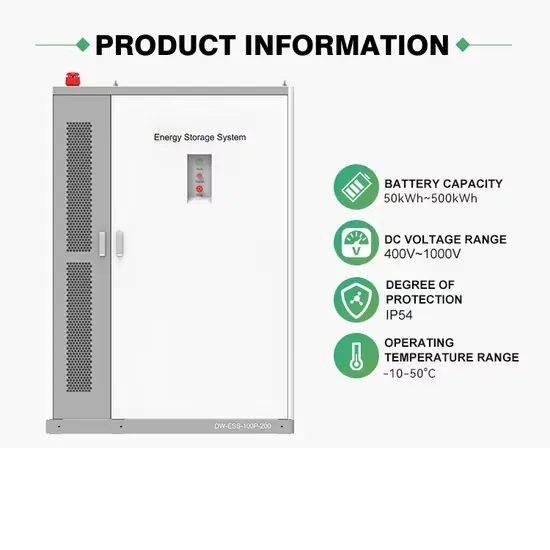

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.