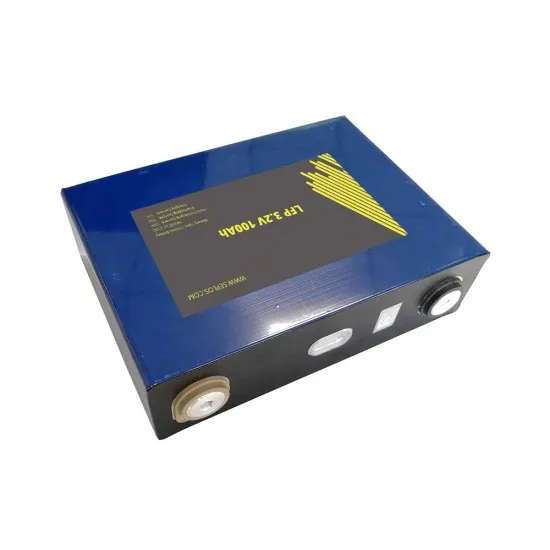

Choose Cold Weather Battery for Low Temperature

Lithium-ion batteries have become the preferred power source for many devices, from smartphones to electric vehicles and energy storage

Get a quote

Cold Temperature Start Up of Low Cost Power Supplies with

At ambient temperatures below freezing, these thermistors have very high resistances, and if the supply is "rated" to start-up at a cold temperature, it should have been

Get a quote

Impact of Temperature on Power Supply Reliability

Extreme heat and cold can impact your power supply''s functionality. High temperatures might lead to thermal runaway, reduce the equipment''s lifespan,

Get a quote

Temperature''s Impact on Power Bank Capacity – RUGD Analysis

Many users believe that power banks perform consistently, regardless of temperature. However, temperature significantly affects power bank efficiency and capacity.

Get a quote

Power Supply Issues in Cold Temperatures

We use a relatively old 12V 5A power supply in an unheated room to drive motors for an astronomical observatory. When the temperature gets close to 0C, the power supply

Get a quote

Microsoft Word

However, switching the power supply off and on after it has been running for a while can produce an inrush current many times the cold-start figure. While this is not an issue that affects the

Get a quote

A Buyer''s Guide to Arctic Grade Cable

The cable is insulated with a low-temperature PVC material that allows it to remain pliable and operational in temperatures as low as -40°C. Arctic Grade cables are typically used in

Get a quote

Cold Weather Wire and Cable Installation Ratings and Tips

View the minimum operating temperature and installation temperature of various standard cabling types and learn why they are important to adhere to.

Get a quote

TA04-High Temperature Challenges and Solutions for Power

Typically, the operating temperature range for power supplies is between 0°C and 40°C, with some products able to reach standards of 0°C to 50°C. In other words, the temperature inside

Get a quote

Impact of weather changes on the use of wires and cables

Under extremely cold temperature conditions, wires and cables may be damaged, affecting power supply, communications, and data transmission. 1 crease in conductor

Get a quote

Impact of Temperature on Power Supply Reliability

Extreme heat and cold can impact your power supply''s functionality. High temperatures might lead to thermal runaway, reduce the equipment''s lifespan, and reduce component reliability,

Get a quote

Difference Between Regular and Cold Weather

But the opposite is true for outdoor extension cord cold weather. While any water-proof material can be used for insulation, polyvinyl chloride

Get a quote

Cold Temperature Start Up of Low Cost Power

At ambient temperatures below freezing, these thermistors have very high resistances, and if the supply is "rated" to start-up at a cold

Get a quote

Can Cold Weather Cause Electrical Problems? Understanding

Power outages during extreme cold can exacerbate the risks associated with frozen pipes and electrical systems. When temperatures drop, the likelihood of your pipes

Get a quote

The Complete Guide to Electrical and Temperature Measurement

Electrical methods, such as thermocouples and resistance temperature detectors, utilize the electrical properties of materials to determine temperature. Mechanical methods, such as

Get a quote

Microsoft Word

The above characteristics, aging and temperature dependent resistance imply the need for a variable voltage power supply capable of increasing the output voltage by a factor of two (2).

Get a quote

How Lithium-Ion Batteries Perform in Cold Weather?

Some are specifically designed to perform in extreme temperatures, making them a better choice for cold weather use. Look for models labeled as low-temperature or cold

Get a quote

How long is the life of solar outdoor power supply | NenPower

The lifespan of a solar outdoor power supply is generally influenced by various critical factors. 1. Typically, the average lifespan ranges between 25 to 30 years, though

Get a quote

Using Lithium Batteries in Cold Weather

In extreme conditions, one of the most important things to have is a reliable power source. If you want to know what battery is best for your situation, you should first know how

Get a quote

How does temperature affect an outdoor power cord?

As an outdoor power cord supplier, I recommend choosing cords that are specifically rated for the temperature range in which they will be used. Some power cords are designed to withstand a

Get a quote

How Does a Heat Pump Work and How Does

As the temperature warms up outside the COP increases. Compared to electric resistance heat, even at -5 F, a heat pump puts out 2x more heat than a

Get a quote

TEMPERATURE EFFECTS ON MOTOR PERFORMANCE

The maximum power at the elevated temperature is approximately 70% of the maximum power at room temperature. This is a significant change, and it''s a direct consequence of the increased

Get a quote

The Different Temperature Sensor Types and Their Applications

What is a Temperature Sensor? A temperature sensor is a transducer that converts thermal energy (heat) into an electrical signal, voltage, resistance, or current that can

Get a quote

TA04-High Temperature Challenges and Solutions for

Typically, the operating temperature range for power supplies is between 0°C and 40°C, with some products able to reach standards of 0°C to 50°C. In other

Get a quote

power supply

So, if you know the resistance of the wire at ambient temperature, you can calculate its change in resistance at various temperatures. This will help you decide what size

Get a quote

What Is the Minimum Temperature for Outdoor Power Supply

While most outdoor power supplies struggle below -20°C, advanced engineering can extend operational ranges to -40°C or lower. By combining thermal management, smart materials,

Get a quote

6 FAQs about [What is the cold temperature resistance of outdoor power supply ]

What happens if a power supply is cold?

Low power supply temperatures can: Increase the output ripple: The cold can add noise into the system and cause the output voltage ripple to increase, which can waste power. Prevent fully regulated outputs: Low temperatures also affect the power supply’s ability to regulate its output completely.

What is the operating temperature of a power supply?

The operating temperature specified for a power supply refers to the temperature of the environment around it, rather than the external ambient temperature of the equipment. Typically, the operating temperature range for power supplies is between 0°C and 40°C, with some products able to reach standards of 0°C to 50°C.

How does temperature affect a power supply?

Chemical processes accelerate, and mechanical connections can even loosen. The longer a component is operated at high heat, the more elevated temperatures can reduce its lifespan. Reduce the power supply load: Power supplies typically have specified loads according to an ambient temperature range.

Why should you choose a wide temperature power supply?

To address such extreme environments, users are advised to opt for wide temperature (Wide Temperature) power supplies. These devices are designed to provide stable power even under high or low-temperature conditions, ensuring the reliable operation of connected equipment.

What happens if a power supply temperature drops too low?

Electronics generally like the cold, but if the temperature drops too low, it can still cause problems. Low temperatures are more likely to affect performance than a power supply’s lifespan. Low power supply temperatures can:

Why does my power supply not start at cold temperatures?

If electrical characteristics change drastically enough, the power supply may not start at cold temperatures. Increase the risk of electrolytic capacitor seal failure: Extreme cold can cause electrolytic capacitors to fail, a catastrophic failure for the component.

Guess what you want to know

-

What is the normal working temperature of outdoor power supply

What is the normal working temperature of outdoor power supply

-

Outdoor power supply temperature resistance requirements

Outdoor power supply temperature resistance requirements

-

What is the charging and discharging temperature of outdoor power supply

What is the charging and discharging temperature of outdoor power supply

-

What are the specifications of the outdoor power supply in Gambia

What are the specifications of the outdoor power supply in Gambia

-

What is outdoor emergency power supply

What is outdoor emergency power supply

-

What kind of battery is used for Seychelles outdoor power supply

What kind of battery is used for Seychelles outdoor power supply

-

What is the output of the outdoor power supply

What is the output of the outdoor power supply

-

What is Marshall s outdoor power supply

What is Marshall s outdoor power supply

-

What is the minimum power of outdoor power supply

What is the minimum power of outdoor power supply

-

What kind of battery is suitable for outdoor power supply

What kind of battery is suitable for outdoor power supply

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.