Communication Base Station Energy Solutions

A telecommunications company in Central Asia built a communication base station in a desert region far from the power grid. Due to harsh climate

Get a quote

Battery Communication Failure

Check the communication function of the inverter: Check whether other devices (such as power sensor) connected to the RS485 port of the inverter communicate properly.

Get a quote

Multi-objective cooperative optimization of communication base station

Recently, 5G communication base stations have steadily evolved into a key developing load in the distribution network. During the operation process, scientific dispatching

Get a quote

Optimal configuration for photovoltaic storage system capacity in

In this study, the idle space of the base station''s energy storage is used to stabilize the photovoltaic output, and a photovoltaic storage system microgrid of a 5G base station is

Get a quote

(PDF) A Comprehensive Review on Grid Connected

This review article presents a comprehensive review on the grid-connected PV systems. A wide spectrum of different classifications and

Get a quote

GRID CONNECTED PV SYSTEMS WITH BATTERY

This section applies to any inverter that interconnects with a battery system. This includes PV battery grid connect inverters, battery grid connect inverters and stand-alone inverters.

Get a quote

How to solve Inverter & battery Communication issues

How to solve Inverter & battery Communication issues ?Explore practical tips on resolving communication issues between inverters and batteries, ensuring smooth and

Get a quote

Inverter to battery communication? Important or nice to have?

We get a ton of battery communication and battery-inverter compatibility questions and have turned those into a blog series that''s intended to be a resource for installers,

Get a quote

Optimization of Communication Base Station Battery

In the communication power supply field, base station interruptions may occur due to sudden natural disasters or unstable power supplies. This

Get a quote

How to solve Inverter & battery Communication issues

How to solve Inverter & battery Communication issues ?Explore practical tips on resolving communication issues between inverters and

Get a quote

Control strategy for current limitation and maximum capacity

Under grid voltage sags, over current protection and exploiting the maximum capacity of the inverter are the two main goals of grid-connected PV inverters.

Get a quote

Growatt

First measure the inverter output port and check whether there is a problem on the inverter output side. If there is no problem, the external AC side is disconnected. Check the air

Get a quote

Bad, Better, Best: Battery-Inverter Communications & Compatibility

In this article, we will compare basic and advanced battery communication, discuss the challenge of ''good'' inverter-battery communication, and what happens when it''s

Get a quote

Telecom Base Station Backup Power Solution: Design Guide for

Discover the 48V 100Ah LiFePO4 battery pack for telecom base stations: safe, long-lasting, and eco-friendly. Optimize reliability with our design guide.

Get a quote

Inverter and energy storage battery communication

The performance of any battery-inverter combination depends on how effectively the battery can fulfill this role. For the battery to receive what it needs and for the system to operate at peak

Get a quote

Optimization of Communication Base Station Battery

In the communication power supply field, base station interruptions may occur due to sudden natural disasters or unstable power supplies. This work studies the optimization of

Get a quote

Hybrid Control Strategy for 5G Base Station Virtual

With the rapid development of the digital new infrastructure industry, the energy demand for communication base stations in smart grid

Get a quote

Inverter communication mode and application scenario

The communication rate is low, and the data collector must be connected to the same power loop The characteristics of different communication methods of inverters are obvious, and the

Get a quote

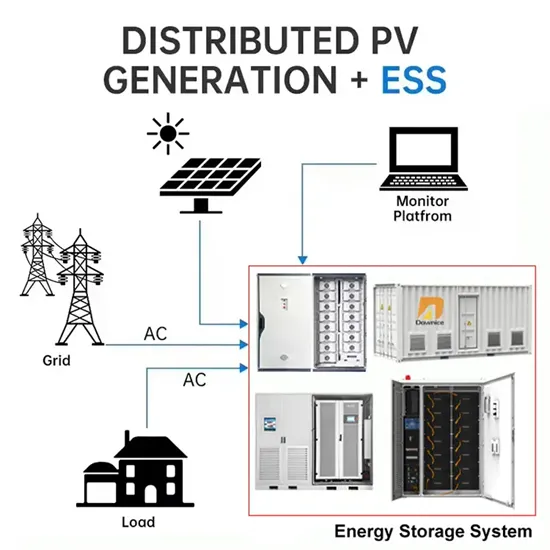

The Future of Hybrid Inverters in 5G Communication Base Stations

Conclusion: As 5G networks expand, hybrid inverters will play a pivotal role in powering next-gen base stations—providing stable, cost-effective, and green energy solutions

Get a quote

How Battery Communication Protocols Fail: RS485 & CAN

3 days ago· Why do failures in battery-inverter communication remain a top complaint in the field? Communication problems are notoriously elusive—they wear many masks. One day it

Get a quote

Optimum sizing and configuration of electrical system for

This study develops a mathematical model and investigates an optimization approach for optimal sizing and deployment of solar photovoltaic (PV), battery bank storage

Get a quote

How Solar Energy Systems are Revolutionizing Communication Base Stations?

Energy consumption is a big issue in the operation of communication base stations, especially in remote areas that are difficult to connect with the traditional power grid,

Get a quote

solar power for Base station

The solar power for base station solution provides an economical and efficient energy solution for communication base stations, reducing operating costs, emissions, and improving energy

Get a quote

6 FAQs about [Communication base station inverter grid-connected battery problem]

How does a battery-inverter system work?

In a power system with closed-loop communication, the inverter, solar charge controllers, and other components do not control the battery. Instead, the battery informs the decisions made by everything else in the system. The performance of any battery-inverter combination depends on how effectively the battery can fulfill this role.

What makes a good battery-inverter combination?

The performance of any battery-inverter combination depends on how effectively the battery can fulfill this role. For the battery to receive what it needs and for the system to operate at peak performance, these control messages must be accurate and well-understood by the rest of the system. As you will see, this is not always a given.

Are budget battery companies compatible with inverters?

Most budget battery companies don’t have support from the inverter companies they claim compatibility with. Rather, they reverse-engineer communication protocols established by officially supported brands or simply buy and incorporate their BMS boards.

What happens if a battery inverter fails?

In summary, incomplete or inconsistent battery-inverter communication can: Confuse and frustrate the end user and installer providing tech support. Obscure the true point of failure, delaying resolution. Reduce the battery's life if unknown or poorly understood issues are allowed to persist. Damage confidence in the system and the brand.

What is a basic battery communication system?

As you will see, this is not always a given. In a basic battery communication system, the main information shared is the battery telling the inverter whether or not it will accept or give a current at this moment. A system with basic communication offers reliability and noticeable performance advantages over non-communicating lithium batteries.

What are the characteristics of different communication methods of inverters?

The characteristics of different communication methods of inverters are obvious, and the application scenarios are different. In order to better weave the underlying network of energy digitization and intelligent development, choose the most appropriate communication method according to local conditions.

Guess what you want to know

-

Communication base station inverter grid-connected battery problem

Communication base station inverter grid-connected battery problem

-

Côte d Ivoire communication base station inverter grid-connected battery

Côte d Ivoire communication base station inverter grid-connected battery

-

How to measure the grid-connected battery capacity of a communication base station inverter

How to measure the grid-connected battery capacity of a communication base station inverter

-

Communication base station inverter grid-connected photovoltaic power generation

Communication base station inverter grid-connected photovoltaic power generation

-

Philippines Communication Base Station Inverter Grid-Connected New Infrastructure Project

Philippines Communication Base Station Inverter Grid-Connected New Infrastructure Project

-

Burkina Faso Communication Base Station Inverter Grid-Connected Infrastructure Project

Burkina Faso Communication Base Station Inverter Grid-Connected Infrastructure Project

-

Andorra communication base station inverter grid-connected manufacturer

Andorra communication base station inverter grid-connected manufacturer

-

Communication base station inverter grid-connected access equipment

Communication base station inverter grid-connected access equipment

-

Indoor communication base station inverter battery

Indoor communication base station inverter battery

-

Bangladesh communication base station inverter grid-connected company ranking

Bangladesh communication base station inverter grid-connected company ranking

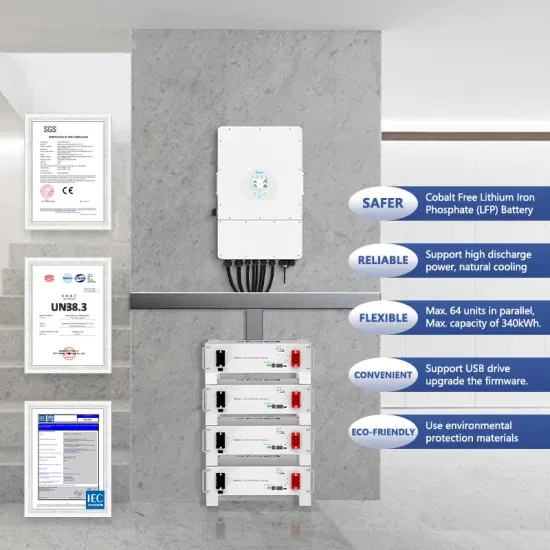

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.