Understanding regenerative braking in electric

In an ac induction motor, the inverter controls the ac supply''s frequency and phase to control the motor''s speed and torque. In regenerative

Get a quote

How Regenerative Braking Works and Its Impact on Electric

At its core, regenerative braking is a system that allows a vehicle to recapture energy that would otherwise be lost during braking. This not only enhances energy efficiency

Get a quote

Regenerative Braking Systems in Electric Vehicles: A

The ability of brake-by-wire systems to dynamically and precisely distribute braking force between regenerative electric braking and hydraulic

Get a quote

Regenerative Braking Systems in Electric Vehicles: A

The ability of brake-by-wire systems to dynamically and precisely distribute braking force between regenerative electric braking and hydraulic friction braking contributes to

Get a quote

Basic principles of regenerative drive operation

In this post we offer an introductory overview of regenerative drive operation (also referred to as "Active Front End" or "AFE"), covering the basic principles and requirements.

Get a quote

Regenerative Braking Control of the Brushless DC Motor Drive

This project introduces a modified six-switch inverter strategy for providing brake torque and regenerative capability. It also details the supporting hardware and controls necessary to

Get a quote

Regenerative Braking Systems in Electric Vehicles

How Regenerative Braking Works in Electric Vehicles In an electric vehicle, the electric motor plays a dual role: it powers the wheels to drive the

Get a quote

Basic principles of regenerative drive operation

In this post we offer an introductory overview of regenerative drive operation (also referred to as "Active Front End" or "AFE"), covering the basic

Get a quote

Understanding the Role of VFD Energy-Regeneration

In the context of VFDs, these units play a crucial role in improving energy efficiency. It rapidly consumes the regenerative energy generated during the

Get a quote

Braking of Frequency Inverter

The braking unit, called "frequency inverter energy braking unit", or "frequency inverter energy feedback unit", is mainly used to control heavy mechanical loads and very fast

Get a quote

Regenerative braking: A closer look at the methods

EV Engineering News Regenerative braking: A closer look at the methods and limits of regen Posted October 3, 2018 by Jeffrey Jenkins & filed

Get a quote

Power converter circuits for recuperation of the regenerative

The role and significance of regenerative braking systems is described and the main requirements for DC/DC converters in regenerative braking systems are presented.

Get a quote

(PDF) Regenerative Braking Systems in Electric

Based on a systematic analysis of 89 peer-reviewed articles from Scopus, it highlights a shift from basic PID controllers to advanced predictive

Get a quote

How do traction inverters behave during regenerative

I have been wanting to know exactly how regenerative braking works in an electric vehicle (3 phase) motor. It''s hard to find details about it on the

Get a quote

What is regenerative braking system and its benefit?

Regenerative braking is a key feature in hybrid electric cars, helping to improve efficiency and save energy. The process happens

Get a quote

Does a Tesla Have a Motor? Electric Motors Explained

3 days ago· The Role of the Motor in Electric Vehicles The motor in a Tesla directly controls vehicle acceleration by delivering instant torque. It adjusts power output instantly, allowing

Get a quote

Understanding the Role of VFD Energy-Regeneration Units in

In the context of VFDs, these units play a crucial role in improving energy efficiency. It rapidly consumes the regenerative energy generated during the emergency braking process of the

Get a quote

What are the applications of regenerative braking inverter devices

From the earlier application of regenerative energy resistor consumption devices in traction substations to the development of capacitive energy storage, flywheel energy storage

Get a quote

Regeneration in Variable Frequency Drives and Energy

The Regenerative power can be dissipated using an arrangement of Brake chopper and Braking Resistor there by the drive will be protected from overvoltage tripping. Also an overvoltage

Get a quote

MATLAB Simulation of Regenerative Braking System in EV

The developed simulation model incorporates key components of the regenerative braking system, including the vehicle dynamics, electric motor/generator, battery model, and the

Get a quote

Understanding the Role of Regenerative Braking Resistors in

Prevents overvoltage on the DC link during braking. Protects the inverter and other sensitive components. Ensures controlled deceleration by allowing the drive to absorb the full

Get a quote

Braking and Regeneration | iKnow Knowledge Base

Because of the heat they dissipate, braking resistors are often mounted outside the cubicle, and should be out of harm''s way and protected against liquid, dirt and fingers. This solution is

Get a quote

An overview of regenerative braking systems

RBSs improve fuel economy, performance, and reduce emissions and brake wear. Evaluation factors that determine RBS effectiveness are presented. High supervisory control

Get a quote

How do traction inverters behave during regenerative braking?

I have been wanting to know exactly how regenerative braking works in an electric vehicle (3 phase) motor. It''s hard to find details about it on the internet. Recuperation utilizes

Get a quote

(PDF) Regenerative Braking Systems in Electric Vehicles: A

Based on a systematic analysis of 89 peer-reviewed articles from Scopus, it highlights a shift from basic PID controllers to advanced predictive algorithms like Model

Get a quote

Regenerative braking method used in converter for traction

For producing a given value of Is in phase with Vs,the PWM inverter produces an ac input voltage V1 of given phase and magnitude,as shown in phasor diagrams of fig (4) and (5) for motoring

Get a quote

Regenerative inverter drives

Jeff Whiting of Mitsubishi Electric explains how regenerative inverter drives can be applied in industrial environments to save energy and deliver additional operational benefits.

Get a quote

EV Traction Inverter: Powering the Future of Electric

Key Functions of an EV Traction Inverter: DC-to-AC conversion: It converts the battery''s DC power into AC to power the motor. Motor control: It

Get a quote

Guess what you want to know

-

The role of inverter cabinet in power

The role of inverter cabinet in power

-

The role of battery cabinet inverter

The role of battery cabinet inverter

-

The role of inverter AC cabinet

The role of inverter AC cabinet

-

The role of off-grid inverter

The role of off-grid inverter

-

The role of battery power frequency inverter

The role of battery power frequency inverter

-

Inverter power cabinet

Inverter power cabinet

-

The role of installing a cooling system in a battery cabinet

The role of installing a cooling system in a battery cabinet

-

The role of photovoltaic transmission inverter

The role of photovoltaic transmission inverter

-

Does the inverter cabinet have a ground busbar

Does the inverter cabinet have a ground busbar

-

Energy storage cabinet 3v inverter battery price

Energy storage cabinet 3v inverter battery price

Industrial & Commercial Energy Storage Market Growth

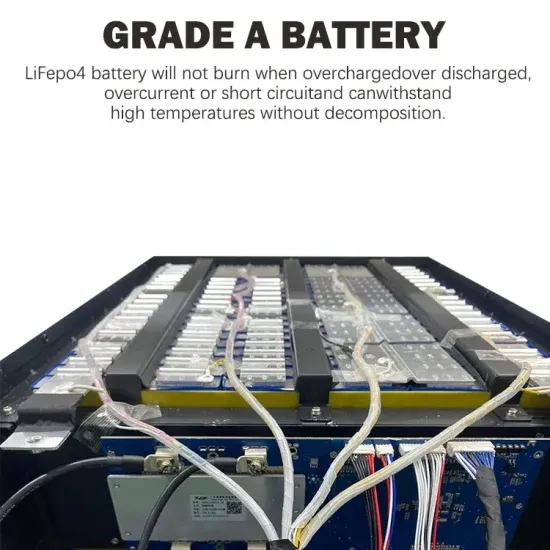

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.