Study on the Impact of Temperature Rise in Transmission

The conductor temperature model measures the conductor temperature, ambient temperature, and solar radiation intensity in real-time, introducing a heat transfer coefficient

Get a quote

Energy storage systems: a review

The world is rapidly adopting renewable energy alternatives at a remarkable rate to address the ever-increasing environmental crisis of CO2 emissions.

Get a quote

jsen-2879427-pp.pdf

The safe operation is guaranteed by enforcing the maximum allowable temperature with respect to the body temperature. The system performance is formulated as the objective function of

Get a quote

Power MOSFET Maximum Ratings

However, the maximum current values in the forward direction are limited by the power loss caused by drain -source on-state resistance, and those in the reverse direction are

Get a quote

What is the temperature requirement of the energy storage

Flywheel energy storage systems operate on the principle of converting kinetic energy into electrical energy. These systems can tolerate a broader temperature variation

Get a quote

HANDBOOK FOR ENERGY STORAGE SYSTEMS

Singapore has limited renewable energy options, and solar remains Singapore''s most viable clean energy source. However, it is intermittent by nature and its output is affected by environmental

Get a quote

ASHRAE Thermal Guidelines for Data Processing

2021 ASHRAE thermal guidelines for data processing environments. Air cooling specs for data centers, including temperature, humidity, and elevation.

Get a quote

ASHRAE TC9.9 Data Center Power Equipment Thermal

In the future more harmonization of product safety standards, such as IEC 60950-1, may be desirable to embrace maximum rated temperature versus an ambient environment

Get a quote

CHAPTER 11 REFRIGERATION

The system classification, allowable refrigerants, maximum quantity, enclosure requirements, location limitations, and field pressure test requirements shall be determined as follows: 1.

Get a quote

New Residential Energy Storage Code Requirements

Find out about options for residential energy storage system siting, size limits, fire detection options, and vehicle impact protections.

Get a quote

Multi-scale modelling of battery cooling systems for grid frequency

The introduction of battery energy storage systems is crucial for addressing the challenges associated with reduced grid stability that arise from the large-scale integration of

Get a quote

Design Considerations for Maximum Temperature per IEC

IEC 61010-1 standard allows determining the maximum temperature levels by measuring the temperature rise under reference test conditions and adding this rise to 40°C or

Get a quote

Thermal management of modern electric vehicle

The operating temperature of Li-ion batteries used in modern electric vehicles should be maintained within an allowable range to avoid

Get a quote

I%I A

pressure rise. The actual pressure rise rate is governed by the complex interaction of external heat leak, fluid temperature stratification, and interfacial heat and mass transfer. If the required

Get a quote

Thermal Performance Evaluation of a Data Center

It was possible to perform allowable operations for approximately 320 s after cooling system outage. Starting at a chilled water supply

Get a quote

00 ReferenceCard portrait.fm

The temperature change of the ITE must meet the limits shown in the table and is calculated to be the maximum air inlet temperature minus the minimum air inlet temperature within the time

Get a quote

Transformer Temperature Rise: A Comprehensive Guide

In the field of power systems, temperature gauges for transformer ratings are more than just a numerical value; they define the limits of the thermal performance of a transformer

Get a quote

What is the temperature requirement of the energy storage system

Flywheel energy storage systems operate on the principle of converting kinetic energy into electrical energy. These systems can tolerate a broader temperature variation

Get a quote

Review on system and materials requirements for high temperature

In the present review, these requirements are identified for high temperature (>150 °C) thermal energy storage systems and materials (both sensible and latent), and the scientific

Get a quote

Transformer Temperature Rise: Understand Ratings,

Transformer temperature rise refers to the increase in winding temperature above the ambient temperature when a transformer operates at full load. It is

Get a quote

Review on system and materials requirements for high

In the present review, these requirements are identified for high temperature (>150 °C) thermal energy storage systems and materials (both sensible and latent), and the scientific

Get a quote

61 Controlling Temperatures in Mass Concrete

By John Gajda and Martha VanGeem Specifications generally limit temperatures in mass concrete to prevent cracking and durability problems. Temperature limits are specified to

Get a quote

Allowable Current Calculation Formula

Allowable Current Calculation FormulaWire/Cable Allowable Current Calculation Formula The maximum continuous current that flows in an insulated wire is

Get a quote

Technology Strategy Assessment

Single-containment vessel systems, or thermocline systems, rely on a temperature gradient across a storage material to store usable energy. To charge or discharge the system, a hot or

Get a quote

Design Considerations for Maximum Allowable Temperature

IEC 61010-1 standard allows to determine the maximum temperature levels by measuring the temperature rise under reference test conditions and adding this rise to 40°C or to the

Get a quote

6 FAQs about [Maximum allowable temperature rise of energy storage system]

What is high temperature thermal energy storage?

High temperature thermal energy storage offers a huge energy saving potential in industrial applications such as solar energy, automotive, heating and cooling, and industrial waste heat recovery. However, certain requirements need to be faced in order to ensure an optimal performance, and to further achieve widespread deployment.

What if a temperature exceeds a maximum allowed temperature?

IEC 60950-1, IEC 62368-1 and IEC61010-1 standards provide rules if exceeding maximum allowed temperature is required for functionality. In such cases for example the equipment must be marked with standardized IEC 60417-5041 (2002-10) symbol. Exceeding maximum allowed temperature per IEC 60601-1 must be documented in Risk Management File.

What is a maximum operating temperature?

Maximum operating temperatures apply to components/materials including those that carry, support, or contain hazardous voltage or current. As an example, a plastic enclosure has two temperature ratings, maximum surface temperature, and its own maximum operating ambient air temperature.

How is energy stored in sensible heat?

In sensible heat, energy is stored by raising the temperature of a medium. The amount of energy stored is proportional to the physical properties of the storage material, including density, volume, specific heat, and temperature change of the storage material .

How much temperature can a data center rise?

e the data center can rise by as much as 30oC (54°F) in a matter of minutes. Locating UPS systems and their respective batteries in separate, grey area spaces with independ nt HVAC systems alleviates the concerns regarding economization of data halls.A complete discussion o

What is high-temperature thermal energy storage (httes) heat-to-electricity (CSP)?

High-temperature thermal energy storage (HTTES) heat-to-electricity TES applications are currently associated with CSP deployments for power generation. TES with CSP has been deployed in the Southwestern United States with rich solar resources and has proved its value to the electric grid.

Guess what you want to know

-

Energy storage battery temperature rise

Energy storage battery temperature rise

-

Energy storage battery low temperature

Energy storage battery low temperature

-

The maximum unit of energy storage of solar panels

The maximum unit of energy storage of solar panels

-

Energy storage power station temperature control system

Energy storage power station temperature control system

-

Maximum energy storage project size in mwh

Maximum energy storage project size in mwh

-

Australian energy storage temperature control system manufacturer

Australian energy storage temperature control system manufacturer

-

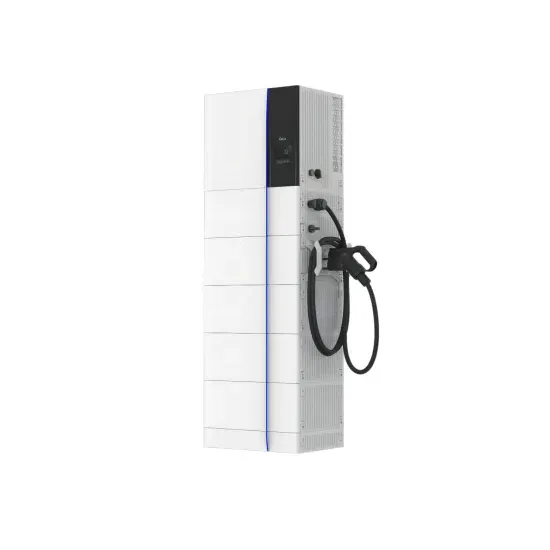

Energy storage charging pile storage temperature

Energy storage charging pile storage temperature

-

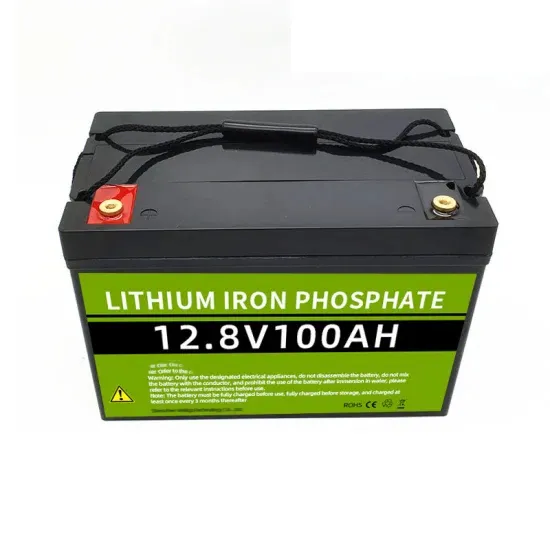

Mongolian energy storage low temperature lithium battery

Mongolian energy storage low temperature lithium battery

-

Ethiopia energy storage low temperature lithium battery

Ethiopia energy storage low temperature lithium battery

-

Mobile energy storage site inverter monitoring temperature and humidity

Mobile energy storage site inverter monitoring temperature and humidity

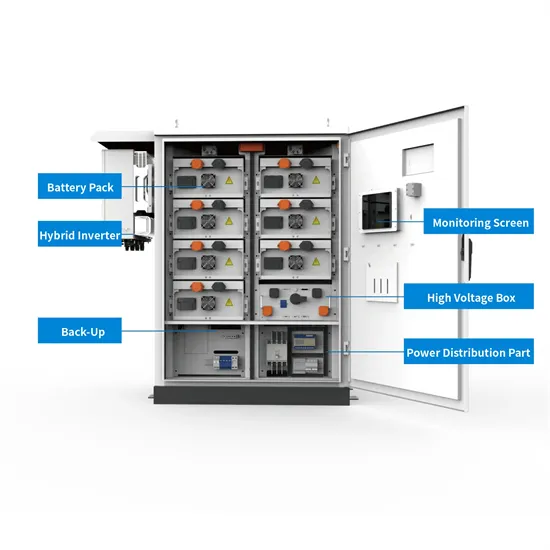

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.