Comparison of Battery balancing methods: Active cell

To address this issue and improve the lifetime of battery packs, cell balancing methods have been developed. These methods can be broadly

Get a quote

Battery Management System Automotive Applications | Vishay

BMS (Battery Management System) is important electronic control unit for EV/HEV vehicle, which including battery monitor and battery balancing units. In multi-battery packs no two cells are

Get a quote

What is the difference between active BMS and passive BMS

Enter BMS, the intelligent guardian angel of batteries that ensures they stay charged, balanced, and protected from any potential harm. In this blog post, we''ll delve into

Get a quote

What is cell balancing in a BMS and why is it important

Passive cell balancing occurs when a cell''s voltage exceeds a certain threshold, and the BMS activates a resistor to dissipate the excess

Get a quote

Cell Balancing Techniques in Lithium Battery BMS: Passive vs.

Explore the key differences between passive and active cell balancing techniques in lithium battery BMS systems. Learn how each method impacts performance, safety, and

Get a quote

Passive Battery Cell Balancing | Analog Devices

Precision single-chip and multichip battery management systems (BMS) combine battery monitoring (including SoC measurements) with passive or active cell balancing to

Get a quote

Why the cell balancing in bms is necessary for your

Cell balancing in BMS is essential for maximizing the potential of modern energy storage devices like batteries, enabling us to live life to the

Get a quote

Tests of BMS Battery Management System with active

The tests of two BMS Battery management systems, equipped with active and passive systems of balancing the battery capacity, realized

Get a quote

Active Balancing vs Passive Balancing Differences

Active balancing is more accurate and faster than passive balancing. On the other hand, passive balancing relies on Ohm''s Law and the natural cell and balance resistor

Get a quote

Passive Cell Balancing in BMS/BMU Systems: When Simplicity

As battery-based systems scale, from EVs to distributed energy storage, designing the right Battery Management System (BMS) and Battery Management Unit (BMU) is

Get a quote

Cell Balancing Techniques in Lithium Battery BMS:

Explore the key differences between passive and active cell balancing techniques in lithium battery BMS systems. Learn how each method

Get a quote

Comparison of Battery balancing methods: Active cell balancing

To address this issue and improve the lifetime of battery packs, cell balancing methods have been developed. These methods can be broadly categorized into four types:

Get a quote

Passive Balancing: A Key Technology for Enhancing Battery

Ongoing advancements in BMS technologies are likely to further enhance the effectiveness of both passive and active balancing methods, contributing to safer, more

Get a quote

Battery Cell Balancing: What to Balance and How

ABSTRACT Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. The means used to perform cell balancing

Get a quote

Active Balancing vs Passive Balancing Differences

Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Get a quote

Passive Balancing in Battery Management System for Electrical

Using active and passive cell balancing techniques can solve this issue. The right cell balancing technique can shorten the battery pack''s equalization time and enhance its ageing. This paper

Get a quote

A critical review of battery cell balancing techniques, optimal

Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Get a quote

Active balancing vs. Passive balancing in Battery BMS

Active balancing and passive balancing are two methods used in battery management systems (BMS) to ensure that all cells within a battery pack maintain similar

Get a quote

Optimal Cell Balancing in BMS: Reviewing Key Techniques for Battery

Examine the best strategies for cell balancing in BMS using redox shuttle, lossless, active, and passive methodologies.

Get a quote

Battery Balancer Guide: Optimize Performance & Longevity

Battery balancing and balancers optimize performance, longevity, and safety. This guide covers techniques and tips for choosing the right balancer.

Get a quote

SPICE Model of a Passive Battery Management System

The BMS model consists of a modular approach, with the following blocks used in the implementation: cell voltage sensing, battery pack current sensing, cell balancing, power

Get a quote

Active balancing: How it works and what are its

Most battery management systems (BMS) today include passive balancing to periodically bring all cells in series to a common SOC value.

Get a quote

Active balancing vs. Passive balancing in Battery BMS

Active balancing and passive balancing are two methods used in battery management systems (BMS) to ensure that all cells within a battery

Get a quote

BMS Cell Balancing | Active cell balancing | Passive Cell Balancing

Hi everyone!!One of the major control algorithm of Battery Management System is Cell Balancing.Cell balancing is the process of equalizing the voltages among...

Get a quote

What is cell balancing in a BMS and why is it important

Passive cell balancing occurs when a cell''s voltage exceeds a certain threshold, and the BMS activates a resistor to dissipate the excess energy. This process continues until

Get a quote

Guess what you want to know

-

Burundi BMS Battery Management Control System

Burundi BMS Battery Management Control System

-

Chilean Battery Management System BMS

Chilean Battery Management System BMS

-

24V BMS Battery Management System

24V BMS Battery Management System

-

Lebanon energy storage battery bms management system

Lebanon energy storage battery bms management system

-

Bms battery management system products

Bms battery management system products

-

Syria BMS battery management power system composition

Syria BMS battery management power system composition

-

BMS battery management system price trend

BMS battery management system price trend

-

Russian BMS battery management control system brand

Russian BMS battery management control system brand

-

Tonga lithium battery BMS balancing

Tonga lithium battery BMS balancing

-

Latvian BMS battery management costs

Latvian BMS battery management costs

Industrial & Commercial Energy Storage Market Growth

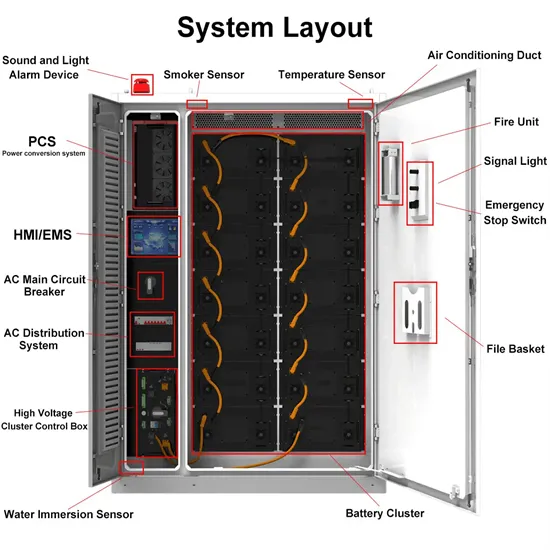

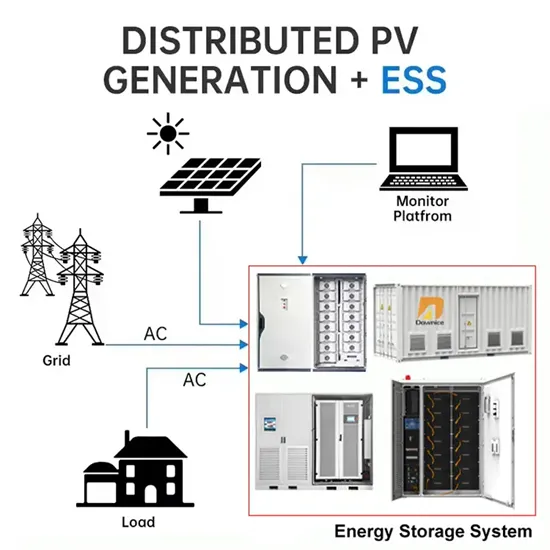

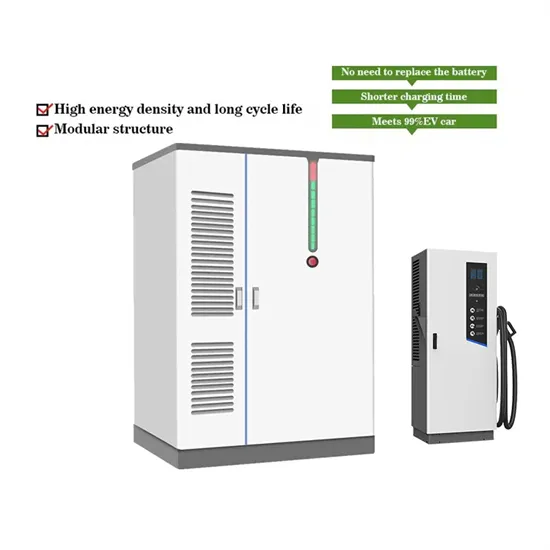

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.