Refrigerators & Freezers Key Product Criteria

Under the National Appliance Energy Conservation Act, the U.S. Department of Energy (DOE) establishes maximum energy consumption standards for consumer refrigeration products.

Get a quote

Reefer Containers 101: A Comprehensive Guide To

Discover how reefer container solutions ensure safe, temperature-controlled shipping for fresh produce and perishable goods worldwide.

Get a quote

Energy Storage Container Technical Specifications

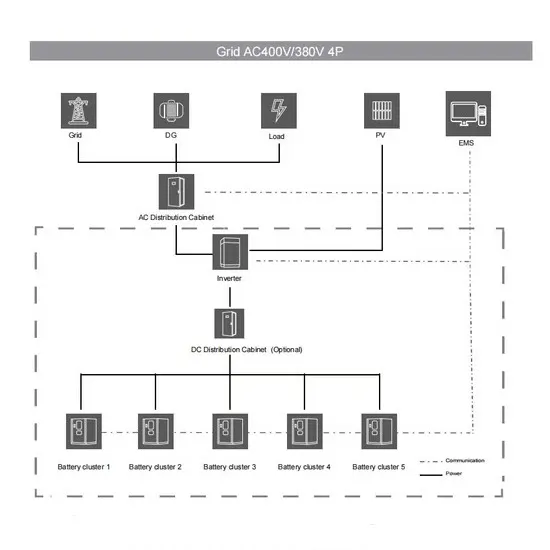

What is a battery energy storage system (BESS) container? This includes features such as fire suppression systems and weatherproofing, ensuring that the stored energy is safe and secure.

Get a quote

U.S. Codes and Standards for Battery Energy Storage Systems

This document provides an overview of current codes and standards (C+S) applicable to U.S. installations of utility-scale battery energy storage systems. This overview highlights the most

Get a quote

Industrial Refrigeration Best Practices Guide, 3rd ed.

Goals Ultimately, improving energy efficiency in industrial refrigeration is achieved by changing the business practices of food-processing companies, cold-storage and refrigerated

Get a quote

Fire Codes and NFPA 855 for Energy Storage Systems

The ESS project that led to the first edition of NFPA 855, the Standard for the Installation of Stationary Energy Storage Systems (released in 2019), originated from a

Get a quote

Container energy storage refrigeration solution

Discover the perfect solution for your cold storage needs with our reliable 20ft refrigerated containers. Get best storage solution from us Our cold storage refrigerated containers,

Get a quote

Standards for Energy Storage Battery Containers: What You

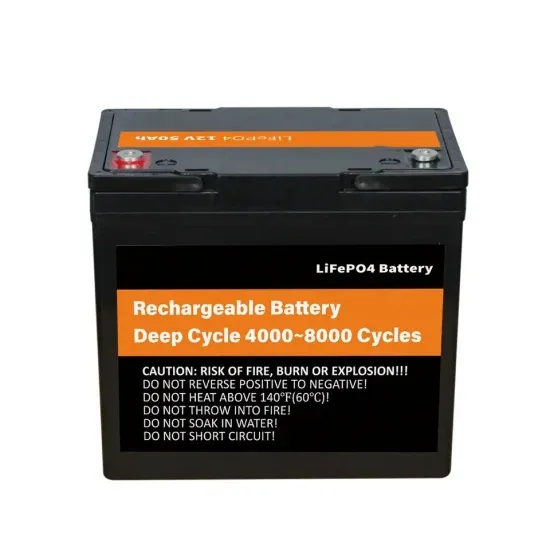

But here''s the kicker—without strict standards for energy storage battery containers, that humming could turn into a disaster. As renewable energy adoption skyrockets, these

Get a quote

Complete Guide to Refrigerated Container Types

Refrigerated storage containers provide the temperature-sensitive solutions needed in countless industries. Also called cold storage containers

Get a quote

Review of Codes and Standards for Energy Storage Systems

The article also gives several examples of industry efforts to update or create new standards to remove gaps in energy storage C&S and to accommodate new and emerging energy storage

Get a quote

Requirements and standards for energy storage container

NFPA 855--the second edition (2023) of the Standard for the Installation of Stationary Energy Storage Systems--provides mandatory requirements for, and explanations

Get a quote

National Standard Specifications for Energy Storage Containers

The relevant codes for energy storage systems require systems to comply with and be listed to UL 9540 [B19], which presents a safety standard for energy storage systems and equipment

Get a quote

BESS Container Sizes: How to Choose the Right

In this guide, we''ll explore standard container sizes, key decision factors, performance considerations, and how to select the best size for your

Get a quote

Microsoft Word

Until existing model codes and standards are updated or new ones developed and then adopted, one seeking to deploy energy storage technologies or needing to verify an installation''s safety

Get a quote

Reefer Container Temperature Range & Chart

To ensure safe and effective storage & warehousing, it''s important to understand the refrigerated container temperature range, how to set it correctly, and how

Get a quote

Energy storage battery container refrigeration

Businesses also install battery energy storage systems for backup powerand more economical operation. These "behind-the-meter" (BTM) systems facilitate energy time-shift arbitrage,in

Get a quote

Energy Storage Containers: Reshaping The Future Of

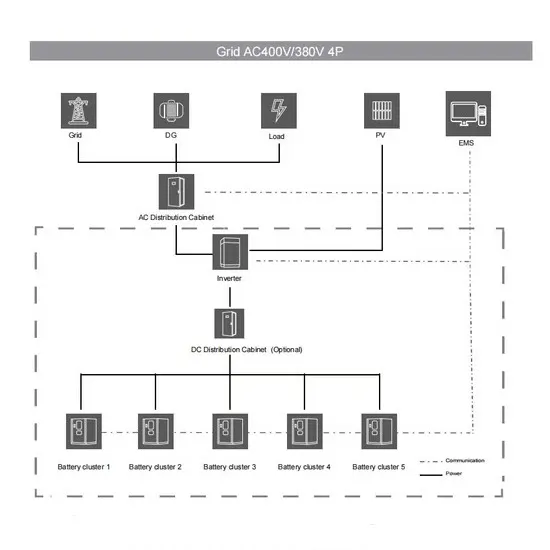

To solve these problems, energy storage containers came into being. Energy storage containers, also known as PCS containers or battery

Get a quote

Energy Storage NFPA 855: Improving Energy Storage

While locally adopted fire codes take precedence over NFPA 855, the depth of this standard—plus the wealth of tutorial information in its annexes—make it a valuable resource

Get a quote

Standard cabinets and energy storage containers

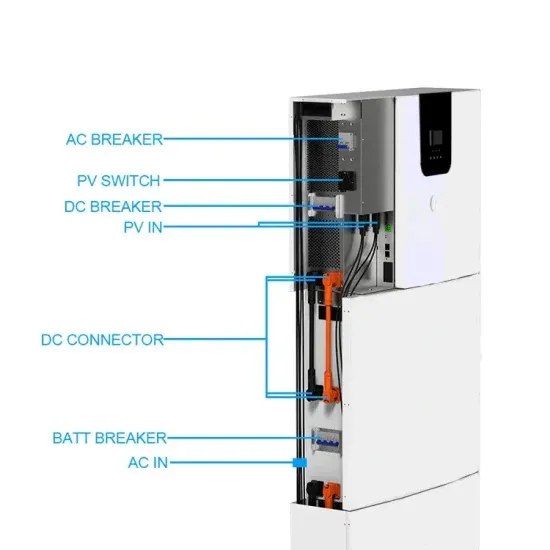

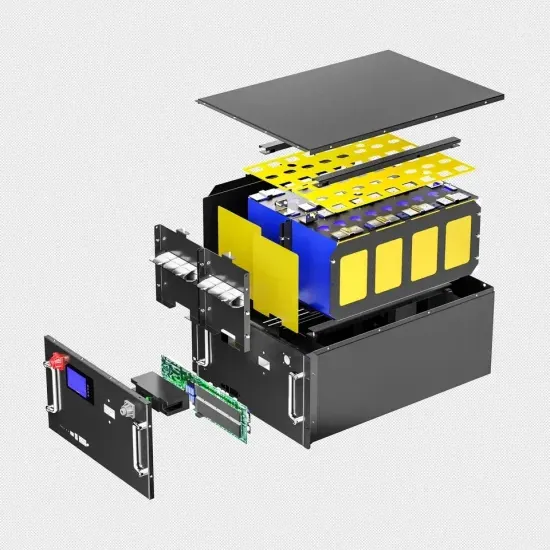

Vericom energy storage cabinet adopts All-in-one design, integrated container, refrigeration system, battery module, PCS, fire protection, environmental monitoring, etc., modular design,

Get a quote

A Comprehensive Guide to Refrigerator Shipping

Refrigerated shipping containers come in two standard sizes: 20ft and 40ft. Choose a size based on the volume of goods and available space at the

Get a quote

Energy Storage Container Certification Standards: What You

Robust energy storage container certification standards stack multiple "slices" to block disaster. For example, CATL''s latest containers combine UL, IEC, and in-house cyber security checks.

Get a quote

6 FAQs about [Which standard should energy storage container refrigeration meet]

What are the energy conservation standards for refrigerators?

Under the National Appliance Energy Conservation Act, the U.S. Department of Energy (DOE) establishes maximum energy consumption standards for consumer refrigeration products. The standards depend on the size, configuration, and functionality specifically: Ice Maker: No-ice maker, automatic ice maker, through the door icemaker.

Do energy storage systems need a CSR?

Until existing model codes and standards are updated or new ones developed and then adopted, one seeking to deploy energy storage technologies or needing to verify an installation’s safety may be challenged in applying current CSRs to an energy storage system (ESS).

What is installation of stationary energy storage systems?

he Installation of Stationary Energy Storage Systems—providesmandatory requirements for, and explanations of, the safety strategies and features of energy storage systems (ESS). Applying to all energy storage technologies, e standard includes chapters for specific technology classes. The depth of this standard makes

What if energy storage system and component standards are not identified?

Energy Storage System and Component Standards 2. If relevant testing standards are not identified, it is possible they are under development by an SDO or by a third-party testing entity that plans to use them to conduct tests until a formal standard has been developed and approved by an SDO.

What are the fire and building codes for energy storage systems?

However, many designers and installers, especially those new to energy storage systems, are unfamiliar with the fire and building codes pertaining to battery installations. Another code-making body is the National Fire Protection Association (NFPA). Some states adopt the NFPA 1 Fire Code rather than the IFC.

Does energy storage need C&S?

Energy storage has made massive gains in adoption in the United States and globally, exceeding a gigawatt of battery-based ESSs added over the last decade. While a lack of C&S for energy storage remains a barrier to even higher adoption, advances have been made and efforts continue to fill remain-ing gaps in codes and standards.

Guess what you want to know

-

Which manufacturers of energy storage container conveyor belts are there

Which manufacturers of energy storage container conveyor belts are there

-

Which lithium-ion battery energy storage container is best in India

Which lithium-ion battery energy storage container is best in India

-

Which energy storage container power station is best in Brazil

Which energy storage container power station is best in Brazil

-

Which nickel-cadmium battery energy storage container is best in Afghanistan

Which nickel-cadmium battery energy storage container is best in Afghanistan

-

Which battery energy storage container is best in Cuba

Which battery energy storage container is best in Cuba

-

The latest standard price of energy storage cabinet container

The latest standard price of energy storage cabinet container

-

Which lithium-ion battery energy storage container is best in Tuvalu

Which lithium-ion battery energy storage container is best in Tuvalu

-

Container energy storage system heat dissipation and refrigeration

Container energy storage system heat dissipation and refrigeration

-

Introduction to the Energy Storage Container Fire Protection System

Introduction to the Energy Storage Container Fire Protection System

-

Huawei New Zealand container energy storage cabinet

Huawei New Zealand container energy storage cabinet

Industrial & Commercial Energy Storage Market Growth

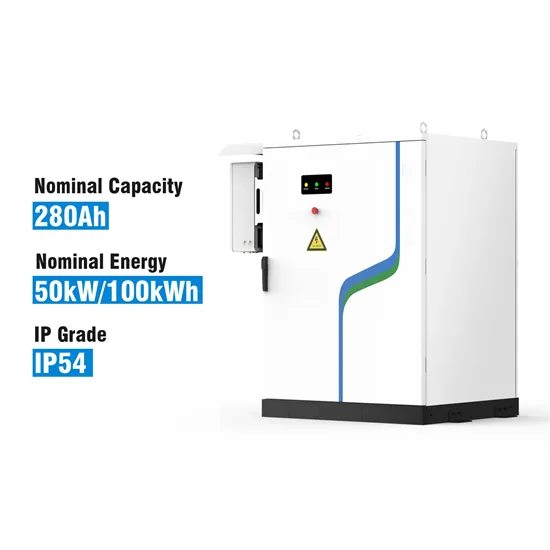

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

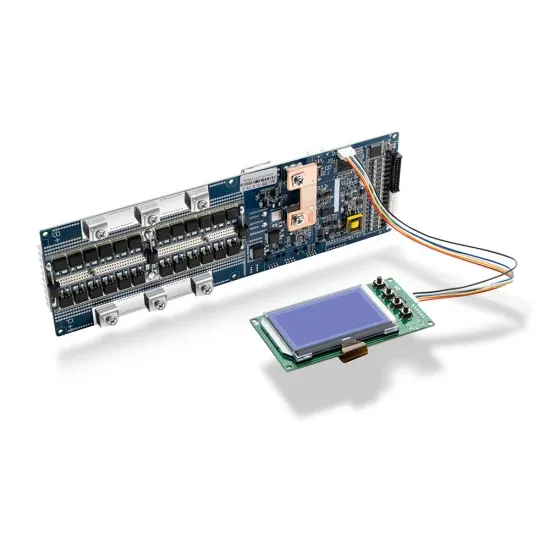

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.