The Ultimate Guide to Solar Combiner Boxes: From Basics to

Solar combiner boxes are integral to solar power systems, serving to combine the outputs of multiple solar panel strings into a single output for the inverter. The effectiveness

Get a quote

A Comprehensive Guide to Combiner Boxes in

Given that solar installations are exposed to the outdoors, combiner boxes often include surge protection to protect the system from voltage spikes caused by

Get a quote

Photovoltaic DC Combiner Box vs. AC Combiner Box: What''s the

This article provides a detailed introduction to the differences between photovoltaic AC combiner boxes and DC combiner boxes, explaining their similarities and differences in

Get a quote

Combiner Box Selection Guide: How to Choose the Right PV DC Box

Learn how to select the right solar combiner box with combiner box selection guide. Compare types, features, voltage ratings, and safety certifications for PV installations.

Get a quote

How to Select the Right PV Combiner Box: Key Parameters and

This parameter refers to the maximum input voltage the PV combiner box can withstand. During selection, the input voltage parameter should be determined based on the

Get a quote

What is a Combiner Box as Used in PV System

The voltage rating of a solar combiner box must align with the maximum voltage of your photovoltaic system. This rating determines the box''s ability to handle the electrical load

Get a quote

What You Need to Know About PV Combiner Boxes

– PV AC Combiner Boxes: Used in AC power systems where the voltage, after being stepped up by transformers at substations, is typically at

Get a quote

How to Choose the Right Combiner Box for Solar

Learn how to choose the best combiner box for your solar system with tips on types, safety, expansion, and installation for all project sizes.

Get a quote

What You Need to Know About PV Combiner Boxes

– PV AC Combiner Boxes: Used in AC power systems where the voltage, after being stepped up by transformers at substations, is typically at high voltage levels like 110kV,

Get a quote

PV panel string and parallel combiner box

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

Get a quote

Connect to long term success with the right DC cables

In the configuration of a central inverter, multiple PV strings are connected in parallel to a DC combiner box, with multiple combiner boxes

Get a quote

Electrical Parameters to Consider When Designing a Combiner Box

The rated voltage of the combiner box determines the maximum voltage it can safely handle. The voltage in a PV system is primarily determined by the series-connected PV modules.

Get a quote

Combiner Box Selection Guide: How to Choose the Right PV DC

Learn how to select the right solar combiner box with combiner box selection guide. Compare types, features, voltage ratings, and safety certifications for PV installations.

Get a quote

String combiner for solar power | Phoenix Contact

The string combiner box collects and distributes the string currents from the solar panels. In addition, the string combiner box monitors the system performance and protects the individual

Get a quote

What is DC PV Solar Combiner Box

The Solar combiner box in the photovoltaic power generation system is a wiring device that ensures orderly connection and convergence of photovoltaic modules.

Get a quote

Working on Solar Wiring and Fusing (EB-2023-0676)

EB-2023-0676 | October 2023 Working on Solar Wiring and Fusing Introduction Figure 1. Wiring a simple solar photovoltaic (PV) system with a

Get a quote

The Ultimate Guide to Solar Combiner Boxes: From

Solar combiner boxes are integral to solar power systems, serving to combine the outputs of multiple solar panel strings into a single output for

Get a quote

Electrical Parameters to Consider When Designing a Combiner

The rated voltage of the combiner box determines the maximum voltage it can safely handle. The voltage in a PV system is primarily determined by the series-connected PV modules.

Get a quote

Combiner Box Output Voltage/Current help

Just to answer directly, yes combiner boxes are usually for combining all the positive inputs together to one positive output, and all the negative inputs together to one

Get a quote

Rated voltage range of photovoltaic combiner box

When selecting a photovoltaic (PV) combiner box, several key parameters must be considered to ensure the efficient operation and safety stability of the PV power station.

Get a quote

Exploring the Significance and Functionality of Solar

Efficient components like solar combiner boxes are at the forefront of this transformation, facilitating safer, smarter, and more eco-friendly solar

Get a quote

High current generator junction box

Bifacial PV modules have solar cells on both the back and the front of the panel. This allows solar energy to be collected on the back of the panel and increases the energy yield of the solar

Get a quote

A Comprehensive Guide to Combiner Boxes in Photovoltaic

Given that solar installations are exposed to the outdoors, combiner boxes often include surge protection to protect the system from voltage spikes caused by lightning or other electrical

Get a quote

PV Combiner Box Components | DC Breaker, SPD,

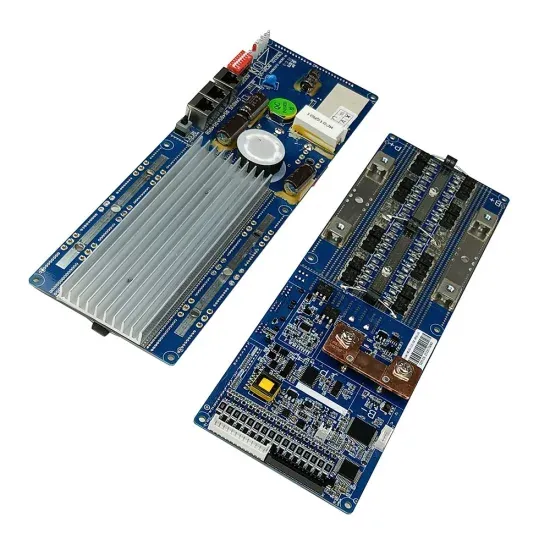

The performance and safety of a PV combiner box rely heavily on the quality of its internal electrical components. LETOP uses and offers a range of rigorously

Get a quote

Photovoltaic Combiner Box Voltage: Critical Insights for Solar

But here''s the kicker: combiner box voltage management often determines whether your solar project succeeds or fails spectacularly. Recent data from the 2023 Gartner Energy Report

Get a quote

6 FAQs about [Is the photovoltaic combiner box considered high voltage]

How to select a PV combiner box?

The input voltage parameter is another important consideration in the selection of a PV combiner box. This parameter refers to the maximum input voltage the PV combiner box can withstand. During selection, the input voltage parameter should be determined based on the rated and maximum voltages of the PV panel array.

What is a combiner box in a photovoltaic system?

In a photovoltaic system, a combiner box acts as a central hub that consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring structure, enhance system security and simplify maintenance procedures.

What is the input power parameter of a PV combiner box?

The input power parameter is one of the key considerations in the selection process. It refers to the maximum input power that the PV combiner box can handle. When selecting, it’s necessary to determine the input power parameter of the PV combiner box based on the total installed capacity and expected power generation of the PV power station.

What is a solar combination box?

A Solar Combiner Box is an essential electrical device used in photovoltaic (PV) power generation systems. Its primary function is to combine the output currents of multiple solar panel strings (PV strings) into a single output, which is then sent to the inverter for DC to AC conversion.

What are advanced solar combiner boxes?

Advanced solar combiner boxes are integrating cutting-edge technologies to enhance system performance, safety, and reliability.

Do you need a solar combiner box?

Adaptability: While smaller residential systems may not require a combiner box if they have only one to three strings, larger systems—ranging from four strings up to thousands—benefit greatly from their use. This adaptability makes combiner boxes suitable for both residential and commercial applications. II. Basics of PV Solar Combiner Boxes

Guess what you want to know

-

The voltage of a photovoltaic combiner box

The voltage of a photovoltaic combiner box

-

Photovoltaic power generation structure combiner box

Photovoltaic power generation structure combiner box

-

How many groups of photovoltaic panels are required to install a combiner box

How many groups of photovoltaic panels are required to install a combiner box

-

Photovoltaic combiner box market

Photovoltaic combiner box market

-

Niger Photovoltaic Smart Combiner Box

Niger Photovoltaic Smart Combiner Box

-

Photovoltaic panels with low voltage and high current

Photovoltaic panels with low voltage and high current

-

Hungarian combiner box photovoltaic

Hungarian combiner box photovoltaic

-

Photovoltaic AC combiner box transaction price

Photovoltaic AC combiner box transaction price

-

Photovoltaic combiner box current measurement

Photovoltaic combiner box current measurement

-

Abkhazia outdoor ip65 photovoltaic combiner box merchants

Abkhazia outdoor ip65 photovoltaic combiner box merchants

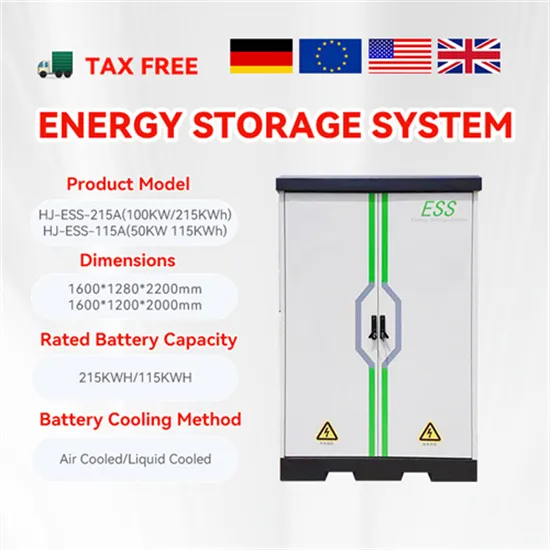

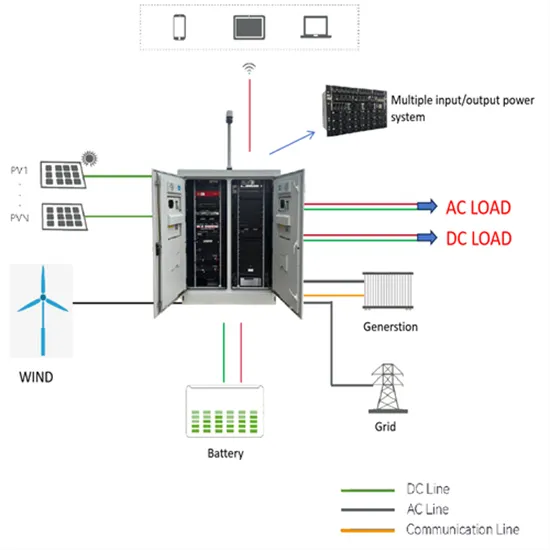

Industrial & Commercial Energy Storage Market Growth

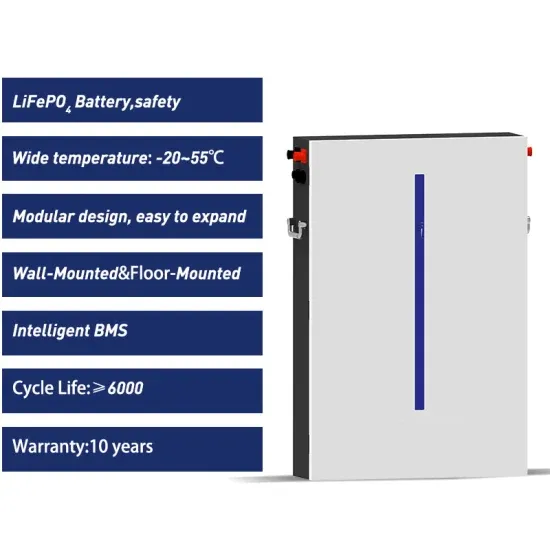

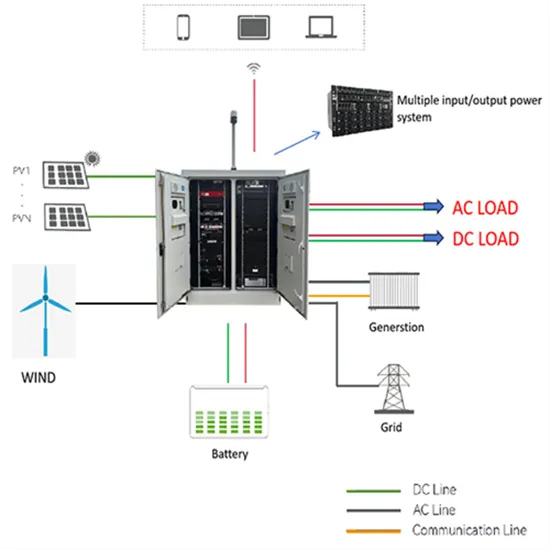

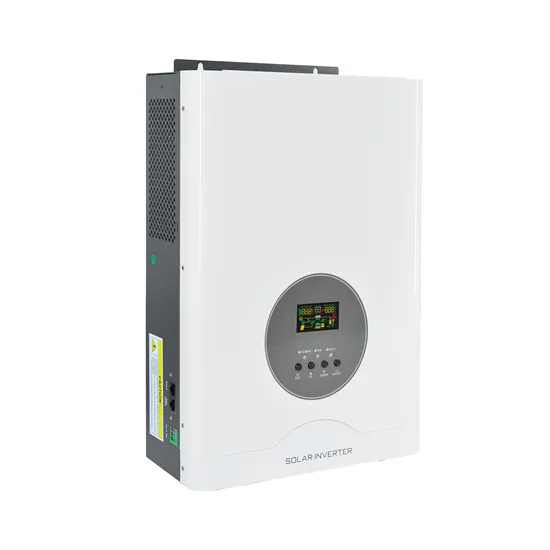

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

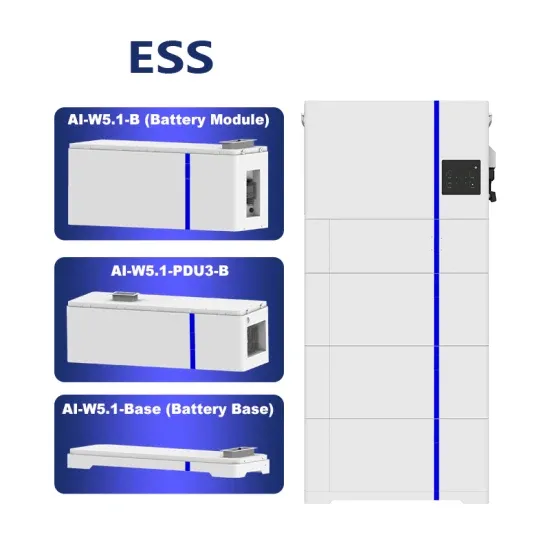

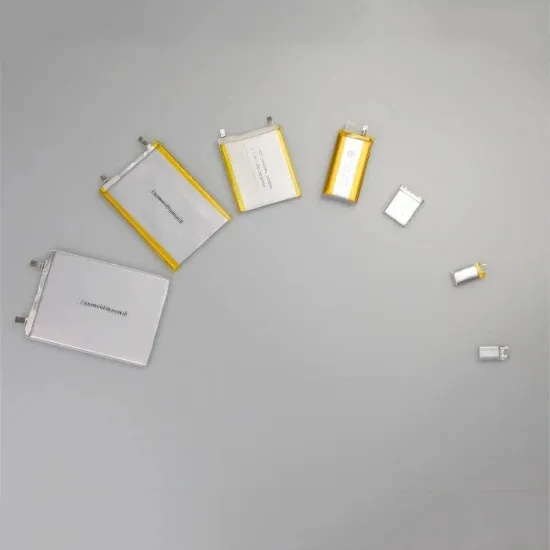

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.