Polycrystalline -

List of Polycrystalline solar panel manufacturers. Directory of companies that make Polycrystalline solar panels, including factory production and power ranges produced.

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get a quote

Onyx Solar, Building Integrated Photovoltaics Solutions

At Onyx Solar, we understand that every project is unique. To meet specific requirements, we offer two advanced photovoltaic (PV) glass technologies: amorphous silicon and crystalline

Get a quote

High-efficiency Module,Longi solar module

LONGi had scaled up high-volume manufacturing of bifacial modules and has become the largest producer of bifacial PV products, with cumulative shipments of bifacial modules surpassing

Get a quote

Bila Solar

Bila Solar is redefining the industry with high-performance panels proudly manufactured in Indiana and ready to power your projects today. Bila Solar''s 550W dual-glass modules are built for

Get a quote

Onyx Solar, Building Integrated Photovoltaics Solutions

At Onyx Solar, we understand that every project is unique. To meet specific requirements, we offer two advanced photovoltaic (PV) glass technologies:

Get a quote

Monocrystalline silicon: efficiency and manufacturing process

For this reason, lower quality silicon is used. Despite this, the monocrystalline silicon solar PV industry has improved considerably. Manufacture of monocrystalline silicon

Get a quote

Top 10 crystalline PV module manufacturer ranking

With production and capacity figures provided by industry analyst IHS Markit, pv magazine provides a rundown of the top 10 crystalline silicon module manufacturers based on

Get a quote

Suniva -America''s Leading Solar Cell Manufacturer

Suniva is America''s oldest and largest monocrystalline solar cell manufacturer in North America. Suniva was founded in 2007, out of one of the world''s foremost photovoltaic

Get a quote

List of photovoltaics companies

Photovoltaics companies include PV capital equipment producers, cell manufacturers, panel manufacturers and installers. The list does not include silicon manufacturing companies.

Get a quote

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable,

Get a quote

Solar Photovoltaic Manufacturing Basics

Silicon PV Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that

Get a quote

High-efficiency Module,Longi solar module

LONGi had scaled up high-volume manufacturing of bifacial modules and has become the largest producer of bifacial PV products, with cumulative

Get a quote

Solar Value Chain – Panel Supply Steps | Bernreuter

Although thin-film solar panels are produced under just one roof, China''s solar industry has focused on the five-step value chain for classic solar cells made

Get a quote

In-Depth Analysis of Photovoltaic Cell Manufacturing Process and

Detailed Analysis of Photovoltaic Cell Manufacturing Process and Cost Analysis (Part 2) Introduction The solar energy industry has seen significant advancements over the

Get a quote

Flexible silicon solar cells with high power-to-weight ratios

A study reports a combination of processing, optimization and low-damage deposition methods for the production of silicon heterojunction solar cells

Get a quote

Top 10 crystalline PV module manufacturer ranking

With production and capacity figures provided by industry analyst IHS Markit, pv magazine provides a rundown of the top 10 crystalline silicon

Get a quote

BIPV Supplier | Photovoltaic (BIPV) Solutions | Gain Solar

Building-integrated photovoltaics (BIPV) are dual-purpose: they serve as both the outer layer of a structure and generate electricity. Gain Solar has supplied a line of high-efficiency solar

Get a quote

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable, weather resistant photovoltaic

Get a quote

The 9 largest solar panel manufacturers in the world

What are the world''s largest solar panel manufacturers? The National Renewable Energy Laboratory''s most recent Solar Industry Update

Get a quote

BIPV Supplier | Photovoltaic (BIPV) Solutions | Gain

Building-integrated photovoltaics (BIPV) are dual-purpose: they serve as both the outer layer of a structure and generate electricity. Gain Solar has supplied a

Get a quote

Onyx Solar, Building Integrated Photovoltaics Solutions

Onyx Solar: Leader in Building Integrated PV Solutions. Custom Photovoltaic Glass for energy generation that enhances energy efficiency and reduces costs.

Get a quote

PVI19_Front_Cover dd

The main goal of Crystalline silicon (c-Si) PV modules Production process equipment producers is to decrease the typically consist of a solar glass front A standard module production process

Get a quote

Experimental and simulation study on the thermoelectric

Abstract This study aims to evaluate and optimize the thermoelectric performance of semi-transparent crystalline silicon photovoltaic (PV) curtain walls. An integrated

Get a quote

The structure of a photovoltaic module

The structure and materials used in the PV panel manufacturing process are very similar independently from the different types of solution. That is why a

Get a quote

Development of lightweight and flexible crystalline silicon solar

Crystalline silicon (c-Si) solar cell modules hold greater than 90% of the solar cell module market share. Despite recent developments in other types of semiconductor cells [1], c

Get a quote

Guess what you want to know

-

Tunisian crystalline silicon photovoltaic panel manufacturer

Tunisian crystalline silicon photovoltaic panel manufacturer

-

Mexican crystalline silicon photovoltaic panel manufacturer

Mexican crystalline silicon photovoltaic panel manufacturer

-

Norwegian monocrystalline silicon photovoltaic panel manufacturer

Norwegian monocrystalline silicon photovoltaic panel manufacturer

-

Oman photovoltaic power generation single silicon panel manufacturer

Oman photovoltaic power generation single silicon panel manufacturer

-

South Africa non-standard photovoltaic solar panel crystalline silicon

South Africa non-standard photovoltaic solar panel crystalline silicon

-

Somalia photovoltaic solar panel manufacturer

Somalia photovoltaic solar panel manufacturer

-

Photovoltaic panel greenhouse sandwich panel manufacturer

Photovoltaic panel greenhouse sandwich panel manufacturer

-

Uzbekistan micro photovoltaic panel manufacturer

Uzbekistan micro photovoltaic panel manufacturer

-

South Ossetia solar photovoltaic panel manufacturer

South Ossetia solar photovoltaic panel manufacturer

-

Photovoltaic solar panel manufacturer in Niue

Photovoltaic solar panel manufacturer in Niue

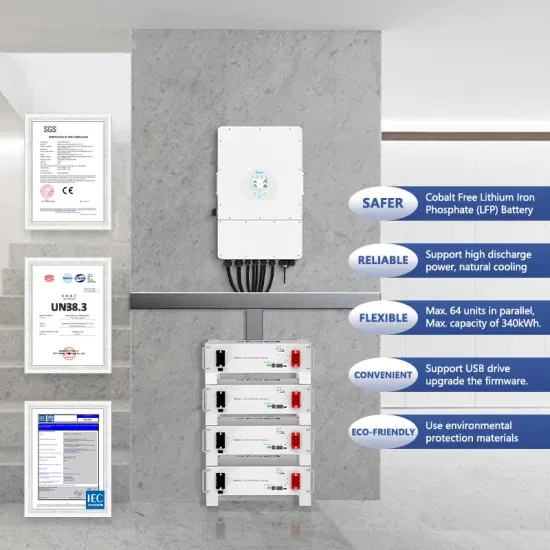

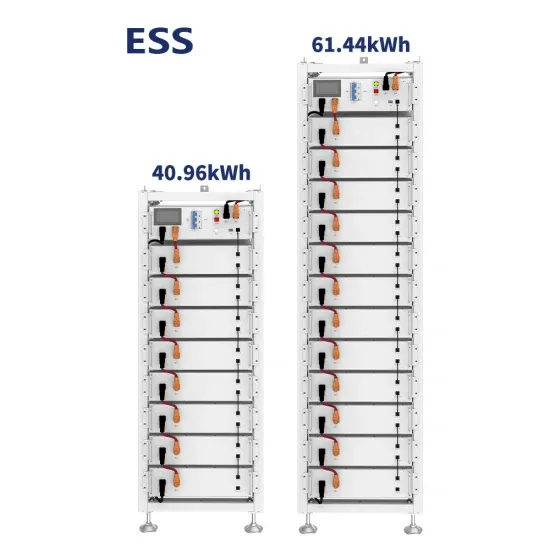

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.