Demonstration of Glass-based 3D Package Architectures with

This paper presents a technology demonstration of two novel 3D glass-based architectures for high performance computing applications. Current 3D technologies ar.

Get a quote

Design and Demonstration of Glass Panel Embedding for 3D

The article, published in 2019 in the Journal of Microelectronics and Electronic Packaging, introduces and demonstrates a novel 3D packaging technology called Glass Panel Embedding

Get a quote

Knowledge graph embedding with self adaptive double-limited loss

Many well-performing embedding models for knowledge graphs employ a negative sampling framework to complete the representation learning in which the loss function is a

Get a quote

Wafer-level manufacturing method for embedding passive element in glass

A wafer-level manufacturing method for embedding a passive element in a glass substrate is disclosed. A highly-doped silicon wafer is dry etched to form a highly-doped silicon mold wafer,

Get a quote

Glass Embedding: New Design Considerations

Presented by Florian Doebbel, Sika Jan. 2019 Learn about the latest glass embedding technologies and applications. Resources Presentation handouts

Get a quote

Microsoft PowerPoint

Traditional methods of setting monolithic glass in railings such as cement‐based grouts may be incompatible with laminated glass. Bolted or clamped systems must be designed and installed

Get a quote

Variable angle photometric characterization of a laminated glass

Glazing units containing sunshading devices (vertical blades, roller shutters, Venetian blinds, etc.) are available on the market nowadays. These products are roughly divided into two families:

Get a quote

Design and Demonstration of Glass Panel Embedding for 3D

This article describes the fabrication process for 3D GPE, leading to demonstration of a technology using embedding of chips with all-Cu interconnections at 40-μm I/O pitch with

Get a quote

Aschenbrenner MRS 2016 Power Embedding

Chip embedding – The key for efficient power electronic solutions R. Aschenbrenner Fraunhofer Institute for Reliability and Microintegration Gustav-Meyer-Allee 25, D – 13355 Berlin,

Get a quote

A 1‐min double embedding method for small tissue

Primary embedding process for a corneum plug: (A) A drop of primary embedding liquid was placed on a glass slide containing the corneum plug; (B and C) the

Get a quote

PVI19_Front_Cover dd

Introduction protection of the cells and other module Of the various module production components from exterior impacts. steps, the embedding process requires PV module set-up

Get a quote

Demonstration of Glass-based 3D Package Architectures with Embedded

This paper presents a technology demonstration of two novel 3D glass-based architectures for high performance computing applications. Current 3D technologies ar.

Get a quote

General Guideline Glass Embedding

This document contains recommendations and hints for the application of SikaForce®-335 GG, a self-levelling polymer grout based on polyurethane resin, for the embedding of monolithic or

Get a quote

GLASS EMBEDDING SAFE AND FAST GLASS

With SikaGlaze® GG-735 the bottom glass edge is embedded in standard U-profiles, and loads are securely transferred through the glass elements thus results in uniform stress distribution.

Get a quote

Sealing & Bonding in Facades

The glasses can be single panes (e.g. laminated glass in the outer skin of the double skin facade) or insulating units with UV-resistant silicone edge sealing and even with argon filling (Sikasil®

Get a quote

2.5D Glass Panel Embedded (GPE) Packages with Better I/O

This paper demonstrates for the first time a next generation high-bandwidth 2.5D glass panel embedding (GPE) architecture with better I/O density, performance,

Get a quote

Designing flexible SERS platforms by embedding double

The main component of SERS enhancement is the double-plasmonic Ag/Au bilayer structure, with the ZIF-8 framework serving as a porous shell to collect target molecules.

Get a quote

Krannich Solar Germany: Double glass solar panels

Double glass solar panels replace traditional polymer backsheets with a glass layer on the back of the module. This design encapsulates the

Get a quote

Glass Package With Multiple Embedded Dies for mmWave

This article presents a multiple-die-embedded glass package that supports a thermal management solution for millimeter-wave (mmWave) applications. The package

Get a quote

Design and Demonstration of Glass Panel Embedding

The article, published in 2019 in the Journal of Microelectronics and Electronic Packaging, introduces and demonstrates a novel 3D packaging technology

Get a quote

Design and demonstration of Glass Panel Embedding for 3D

This paper describes the fabrication process for 3D GPE, leading to demonstration of a technology using embedding of chips with all-Cu interconnections at 40um I/O pitch while

Get a quote

Window Frame Parts Diagram and Breakdown

Explore the components and structure of a window frame through a detailed diagram, understanding the parts and their functions for better window installation and repair.

Get a quote

Component carrier with component embedded in cavity and with double

A component carrier includes a base structure with component carrier material and forming a cavity, a component embedded in the cavity, a first electrically insulating layer structure

Get a quote

6 FAQs about [Double glass component embedding]

Is 3D glass panel embedding a good choice for large package applications?

WLFO promises better performance and form factor at lower costs, but current WLFO packages are mold-based and hence are limited to small packages. This paper presents the first demonstration of 3D Glass Panel Embedding (GPE) technology for high-performance large package applications involving heterogeneous integration.

Can glass panel embedding be used for a large body size heterogeneous integration?

This article presents a 3D packaging technology using glass panel embedding (GPE) for high-performance with potential for large body size heterogeneous integration applications.

Is 3D glass panel embedded a viable solution for large body size integration?

By addressing the critical parameters of die drift and surface planarity, this paper presents the first demonstration of a 3D Glass Panel Embedded (GPE) package for large body size integration with better performance, cost, and reliability than existing technologies.

What is 3D glass panel embedded (GPE)?

This paper demonstrates an advanced 3D Glass Panel Embedded (GPE) packages for heterogeneous integration of digital applications requiring high-density interconnections and RF applications with Through-Glass-Vias (TGVs) integrated in the fan-out region.

What is 2.5D glass panel embedding (GPE)?

This paper presents the first demonstration of a revolutionary new concept in scaling power-efficient bandwidth, cost, large package size and board-level reliability, called 2.5D glass panel embedding (GPE). High temperature and low CTE glass reduces die shifts from tens of microns in current molded fan-out to less than 2 microns in GPE.

What is the best material for glass embedding?

For glass support, use of setting blocks made of SikaForce®-335 GG material used for the glass embedding is recommended. This can avoid stress concentration in the glass edge due to stiffness differences. Regular expansion gaps can reduce stresses in the system that occur out of thermal movement of the different components.

Guess what you want to know

-

Double glass component separation

Double glass component separation

-

Double glass component frame

Double glass component frame

-

Double glass module manufacturers

Double glass module manufacturers

-

Photovoltaic module 72 double glass size

Photovoltaic module 72 double glass size

-

Double glass module rear power

Double glass module rear power

-

Double glass module transmittance adjustable manufacturer

Double glass module transmittance adjustable manufacturer

-

Double glass 265w module parameters

Double glass 265w module parameters

-

Double glass roof

Double glass roof

-

Photovoltaic module double glass frame

Photovoltaic module double glass frame

-

Double glass single glass monocrystalline silicon components

Double glass single glass monocrystalline silicon components

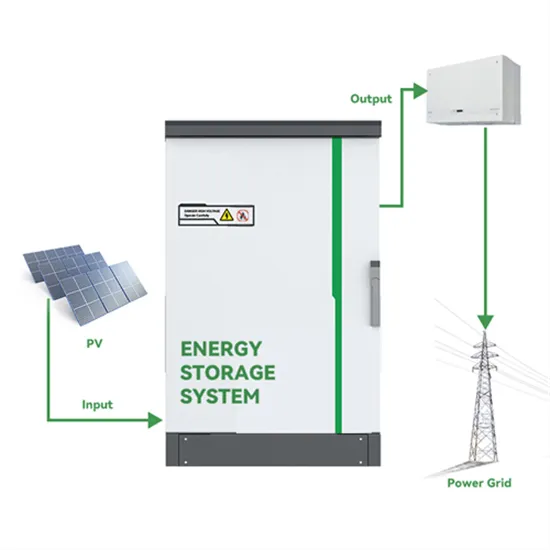

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.