MONOCRYSTALLINE AND POLYCRYSTALLINE

Monocrystalline panels are made from a single, continuous crystal structure, typically silicon. This manufacturing process results in solar cells

Get a quote

Understanding the Composition of Solar Panels

Crystalline Silicon Solar Cells (CSCs) are made up of single-crystal or polycrystalline silicon wafers and have a higher efficiency rate than other

Get a quote

What Are Solar Panels Made Of? Everything You

Monocrystalline solar panels are a type of solar panel produced from a single, large silicon block that''s transformed into silicon wafers.

Get a quote

Exploring the Layers of a Solar Panel Structure

Uncover the essential layers that constitute a solar panel. Understand the composition and function of each layer in this insightful guide.

Get a quote

What Are Solar Panels Made Out Of: Key Components Explained

Monocrystalline Silicon: Made from a single crystal structure, these cells are known for their high efficiency and longevity. Polycrystalline Silicon: Composed of multiple crystal

Get a quote

Monocrystalline solar panels: the expert guide [2025]

What are monocrystalline solar panels? Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which

Get a quote

Breaking Down Solar Panels and What They Are Really Made Of

1 day ago· Solar panels power homes and farms. But what goes into them? Let''s peel back the layers. We''ll look at key parts, materials, and how they come together. If you''re thinking green

Get a quote

How Are Solar Panels Made? – Forbes Home

If you''re new to home solar, you may be wondering, how are solar panels made? This guide will help answer how solar panels are made and what are they made of.

Get a quote

What are solar panels made of? [Materials

Polysilicon, made from silicon metal, is the key material used to make solar cells. This is because its semiconducting properties allow it to

Get a quote

How are Solar Panels Made: A Detailed Overview

Conclusion Charles Frutter made solar panel when the world was unaware of the marvels of solar energy. A solar panel is a futuristic technology

Get a quote

What Are Solar Panels Made Of and How Are They Made?

Solar panels are made of monocrystalline or polycrystalline silicon solar cells soldered together and sealed under an anti-reflective glass cover. The photovoltaic effect

Get a quote

Understanding the Composition of Solar Panels

Monocrystalline solar panels are made from multiple solar cells composed of monocrystalline silicon cells arranged in a grid-like pattern. These thin film solar cell are

Get a quote

What are solar panels made of? [Materials breakdown, 2025]

Polysilicon, made from silicon metal, is the key material used to make solar cells. This is because its semiconducting properties allow it to convert sunlight into electricity (i.e. the

Get a quote

Exploring the Power of Multi-Junction Solar Cells

Researchers and engineers have turned to multi-junction solar cells as a groundbreaking technology in the quest for greater solar panel efficiency. This

Get a quote

4 Types of Solar Panels

Thin-film solar panels are made by depositing a thin layer of photovoltaic material onto a substrate. This manufacturing process makes them lightweight and flexible, allowing for

Get a quote

How Do Solar Panels Work? Solar Energy Explained | Renogy US

Have you ever looked at solar panels on a rooftop and wondered how they actually work? The process is both elegant and efficient. Solar panels harness the power of sunlight through a

Get a quote

How Do Solar Cells Work? Photovoltaic Cells Explained

A solar module comprises six components, but arguably the most important one is the photovoltaic cell, which generates electricity. The

Get a quote

What Are the Solar Panel Structure Materials?

The adoption of renewable energy continues to rise worldwide, with solar technology playing a central role in the global transition to clean power. While most people are familiar with how

Get a quote

What Are Solar Panels Made Of?

The front layer of a solar panel is typically made of tempered glass. This glass is durable and resistant to impact while allowing sunlight to pass through

Get a quote

What Are Solar Panels Made Of? Detailed Materials Breakdown

Monocrystalline Solar Panels: These are made from single silicon crystals, making them the most efficient solar panels available. They have a sleek black appearance and offer

Get a quote

Understanding the Composition of Solar Panels

Monocrystalline solar panels are made from multiple solar cells composed of monocrystalline silicon cells arranged in a grid-like pattern.

Get a quote

What Are Solar Panels Made Of? Detailed Materials

Monocrystalline Solar Panels: These are made from single silicon crystals, making them the most efficient solar panels available. They have a

Get a quote

What Are Solar Panels Made Of? Everything You Need to Know

Monocrystalline solar panels are a type of solar panel produced from a single, large silicon block that''s transformed into silicon wafers. Monocrystalline panels are known for

Get a quote

What Are Solar Panels Made of? Full Materials Guide

The answer to what solar panels are made of is simple: they''re primarily built from silicon solar cells, a protective glass layer, an aluminum frame, wiring, and encapsulation

Get a quote

Organic materials based solar cells

The schematic drawing of a single layer OPV and the energy level diagram has been shown in Fig. 1. The single layer solar cell is fabricated using of only one organic active

Get a quote

6 FAQs about [What are single-layer solar panels made of ]

How are solar panels made?

Silicon is one of the most important materials used in solar panels, making up the semiconductors that create electricity from solar energy. However, the materials used to manufacture the cells for solar panels are only one part of the solar panel itself. The manufacturing process combines six components to create a functioning solar panel.

What materials are used in solar panels?

The main materials used in solar panels, including silicon solar cells, tempered glass, and metal frames. How monocrystalline and polycrystalline solar panels differ in terms of efficiency and cost. The solar panel manufacturing process and how these materials come together to create durable and efficient panels.

What are solar cells made of?

Solar cells are the primary components of any solar panel, responsible for converting light energy into electrical energy. These cells are made from silicon wafers, which can be either monocrystalline or polycrystalline. Monocrystalline Solar Cells: These are made from a single crystal of silicon, resulting in a higher level of efficiency.

How are monocrystalline solar panels made?

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be affixed to a solar panel. Monocrystalline silicon cells are more efficient than polycrystalline or amorphous solar cells.

What are the components of a solar panel?

The primary components of a solar panel are its solar cells. P-type or n-type solar cells mix crystalline silicon, gallium, or boron to create silicon ingot. When phosphorus is added to the mix, the cells can conduct electricity. The silicon ingot is then cut into thin sheets and coated with an anti-reflective layer.

What percentage of solar panels are monocrystalline?

Percentage of a monocrystalline solar panel: 5.2% Polysilicon, made from silicon metal, is the key material used to make solar cells. This is because its semiconducting properties allow it to convert sunlight into electricity (i.e. the photovoltaic effect).

Guess what you want to know

-

What is the specific heat capacity of solar panels

What is the specific heat capacity of solar panels

-

What brand of solar photovoltaic panels is good

What brand of solar photovoltaic panels is good

-

What causes low light transmittance of solar panels

What causes low light transmittance of solar panels

-

What is the price difference between photovoltaic panels and solar panels

What is the price difference between photovoltaic panels and solar panels

-

What does 30wp mean for photovoltaic solar panels

What does 30wp mean for photovoltaic solar panels

-

What is the reasonable value of solar panels

What is the reasonable value of solar panels

-

What is the appropriate thickness of photovoltaic solar panels

What is the appropriate thickness of photovoltaic solar panels

-

What batteries should be used with solar photovoltaic panels

What batteries should be used with solar photovoltaic panels

-

Solar photovoltaic panels in Mexico

Solar photovoltaic panels in Mexico

-

Iraq Garden Solar Panels

Iraq Garden Solar Panels

Industrial & Commercial Energy Storage Market Growth

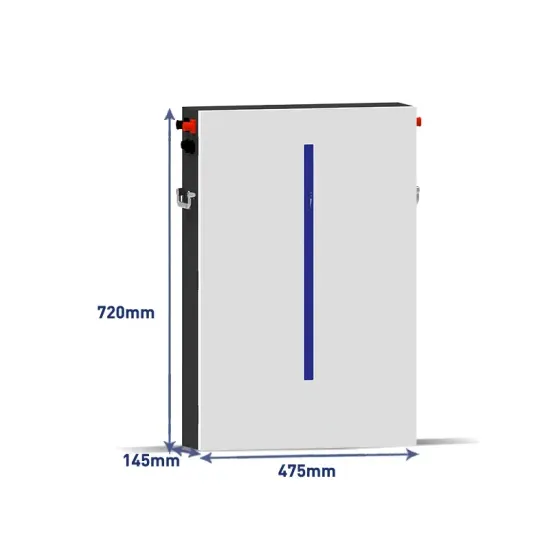

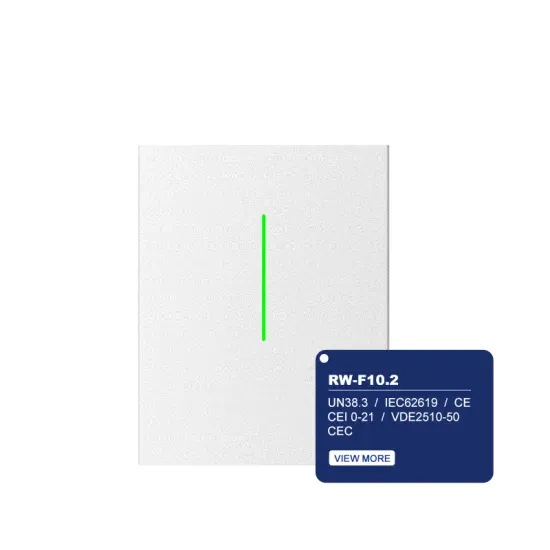

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.