seoul nickel-cadmium battery energy storage container installation

The NiCd battery is a type of rechargeable battery that uses nickel oxide hydroxide and metallic cadmium as its electrode materials. Its operation is based on the electrochemical reactions

Get a quote

Energy Storage Systems

Although Li-ion batteries are the prime concern regarding ESS, NFPA 855 code will also cover lead-acid batteries, nickel-cadmium batteries, sodium batteries and flow batteries. The code

Get a quote

Ni-Cd Block battery range

Saft operates the only plant in the world that produces nickel-cadmium batteries incorporating metals that have been reclaimed on site from spent batteries, reducing their eco-footprint.

Get a quote

Energy storage systems and their optimal application

There are a wide variety of battery technologies for energy storage: lead-acid, sodium-sulfur, nickel-iron, nickel-cadmium, zinc-air, air-iron, lithium-polymer,

Get a quote

Ni-Cd | Saft

Recycling Ni-Cd batteries is a complex process that involves separating the nickel, cobalt and cadmium from the electrodes, a process perfected by Saft''s plant in Oskarshamn, Sweden –

Get a quote

Nickel Cadmium Battery

Nickel-cadmium batteries are solid and reliable rechargeable batteries known for their capability to operate under rigorous conditions, often used in emergency medical equipment and

Get a quote

Battery Storage Tips: Battery Chemistries and the

Appropriate battery storage management and charge management requirements for the battery chemistry may help to extend the life of your

Get a quote

Nickel–Cadmium and Nickel–Metal Hydride Battery Energy Storage

Since the invention of nickel–cadmium (Ni-Cd) battery technology more than a century ago, alkaline batteries have made their way into a variety of consumer and

Get a quote

A Promising Energy Storage System Based on High-Capacity

It has been experimentally proven that hydrogen accumulates in the electrodes of nickel–cadmium batteries in large quantities over the course of their operation. It has been

Get a quote

Metals in Battery Energy Storage Systems: A

Battery metals are crucial for making batteries used in energy storage systems, electric vehicles (EVs), and renewable energy technologies.

Get a quote

Nickel-Cadmium Batteries: A Comprehensive Guide

Discover the benefits and limitations of Nickel-Cadmium batteries in energy storage, including their history, working principle, and uses.

Get a quote

Ni-Cadmium Batteries | SpringerLink

A storage battery has supported a recent rapid expansion of the portable electronic device market and has been developed to the market where a further development has been

Get a quote

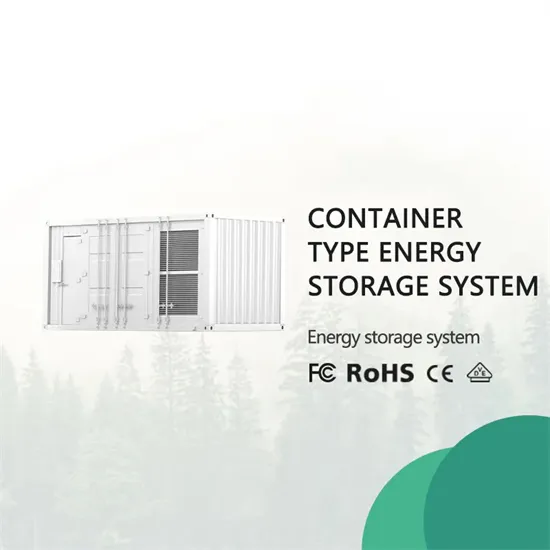

Energy storage container, BESS container

What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard containers to build

Get a quote

BATTERY NICKEL-CADMIUM INFORMATION SHEET

e their container (nickel-plated steel bucket) is designed to resist to such stress. Finally, our batteries are designed to withstand the vibration and differential pressure variations desc

Get a quote

Advancing energy storage: a comparative review of

Among the prominent solutions, nickel–cadmium (NiCd), nickel–metal hydride (NiMH), and sodium-ion (Na-ion) batteries exhibit distinct characteristics, advantages, and

Get a quote

NICKLE CADMIUM (NiCd) BATTERY FOR POWER

Sauer et al. (2007). Detailed cost calculations for stationary battery storage systems. Second International Renewable Energy Storage Conference (IRES II) Bonn, 19.-21.11.2007

Get a quote

A Promising Energy Storage System Based on High

It has been experimentally proven that hydrogen accumulates in the electrodes of nickel–cadmium batteries in large quantities over the course

Get a quote

Different Types of Battery Energy Storage Systems (BESS)

Different types of Battery Energy Storage Systems (BESS) includes lithium-ion, lead-acid, flow, sodium-ion, zinc-air, nickel-cadmium and solid-state batteries.

Get a quote

CATL EnerC+ 306 4MWH Battery Energy Storage

The EnerC+ container is a battery energy storage system (BESS) that has four main components: batteries, battery management systems (BMS), fire

Get a quote

Engineering battery packs for safety and reliability

Battery technologies have evolved from early lead-acid cells used in storage to nickel-cadmium, nickel-metal hydride and polymer batteries. This has today culminated in lithium phosphate

Get a quote

Advancing energy storage: a comparative review of nickel–cadmium

Among the prominent solutions, nickel–cadmium (NiCd), nickel–metal hydride (NiMH), and sodium-ion (Na-ion) batteries exhibit distinct characteristics, advantages, and

Get a quote

Nickel Cadmium Battery

They are equally ideal for industrial UPS applications example for large energy storage for renewable sources. In addition, the energy efficiency in Ni–Cd battery storage depends on the

Get a quote

Metals in Battery Energy Storage Systems: A Comprehensive

Battery metals are crucial for making batteries used in energy storage systems, electric vehicles (EVs), and renewable energy technologies. Key battery metals include

Get a quote

Off-grid | Saft | Batteries to energize the world

Saft operates the only plant in the world that produces nickel-cadmium batteries incorporating metals that have been reclaimed on site from spent batteries, reducing their eco-footprint.

Get a quote

Off-grid | Saft | Batteries to energize the world

Saft operates the only plant in the world that produces nickel-cadmium batteries incorporating metals that have been reclaimed on site from spent batteries,

Get a quote

Energy Storage | Saft | Batteries to energize the world

For example, in Texas, Saft provided battery storage systems to store energy from solar panels, and in Sweden, they replaced diesel generators with battery storage systems for data center

Get a quote

Nickel-Cadmium (NI-CD) Batteries

In commercial production since the 1910s, nickel-cadmium (Ni-Cd) is a traditional battery type that has seen periodic advances in electrode technology and packaging in order to remain viable.

Get a quote

6 FAQs about [Sophia nickel-cadmium battery energy storage container]

Are nickel cadmium batteries safe?

In addition, nickel-cadmium batteries contain metal cadmium that is harmful to the environment and the human body, so nickel-cadmium batteries are gradually withdrawing from the market . The essence of the normal use of lithium batteries refers to the charging and discharging process, which is the basic principle of the battery.

What is a Saft nickel cadmium battery?

Saft nickel cadmium batteries capable of operating at higher temperature with very limited performances changes will allow the end users to reduce their energy consumption by limiting the need to cool down the batterie room.

What is a nickel cadmium battery?

The nickel–cadmium (Ni–Cd) battery consists of an anode made from a mixture of cadmium and iron, a nickel-hydroxide (Ni (OH)2) cathode, and an alkaline electrolyte of aqueous KOH. You might find these chapters and articles relevant to this topic. 2022, Nano Technology for Battery Recycling, Remanufacturing, and Reusing Ziwei Zhao, Tian Tang

What types of batteries are used in battery energy storage systems?

The main types of batteries used in Battery Energy Storage Systems (BESS) include lithium-ion batteries, lead-acid batteries, and flow batteries. Lithium-ion batteries dominate the BESS market, accounting for approximately 90% to 97% of the global grid battery storage market due to their high energy density, long cycle life, and mature technology.

How many cells are in a nickel cadmium aircraft battery?

Nickel-cadmium aircraft batteries generally consist of a steel case containing individual cells connected in series. The number of cells depends on the particular application, but generally 19 or 20 cells are used. The end cells of the series are connected to the battery receptacle located on the outside of the case.

What material is used for a NiCd battery separator?

Two kinds of fabric materials are widely used as separators for NiCd batteries: polyamide (‘nylon’) and polyolefin, which can be polypropylene (PP), or polyethylene (PE), or a combination. In the case of sealed batteries, these fabric materials have proven themselves.

Guess what you want to know

-

Which nickel-cadmium battery energy storage container is best in Afghanistan

Which nickel-cadmium battery energy storage container is best in Afghanistan

-

Which is the best Huijue nickel-cadmium battery energy storage container

Which is the best Huijue nickel-cadmium battery energy storage container

-

Energy storage container battery models and prices

Energy storage container battery models and prices

-

Container Energy Storage System Battery Warranty

Container Energy Storage System Battery Warranty

-

Honduras Lead-Acid Battery Energy Storage Container

Honduras Lead-Acid Battery Energy Storage Container

-

Pakistan Energy Storage Power Station Battery Container

Pakistan Energy Storage Power Station Battery Container

-

Energy storage battery container integration

Energy storage battery container integration

-

India lithium iron phosphate battery energy storage container

India lithium iron phosphate battery energy storage container

-

What is energy storage battery container battery

What is energy storage battery container battery

-

Energy storage battery container refrigeration price

Energy storage battery container refrigeration price

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.