String combiners for solar photovoltaic systems

A video that shows how string combiner boxes are the best plug&play solution for photovoltaic systems, ensuring top protection through high quality components, maximum flexibility thanks

Get a quote

Comparing Central vs String Inverters for Utility-Scale PV Projects

The utility-scale PV market is maturing. Last year, 22.5 GW of utility-scale PV was installed in the US, a 77% jump from 2022. Solar PV accounted for over half (53%) of all new

Get a quote

String and module integrated inverters for single-phase grid

This work presents an overview on recent developments and a summary of the state-of-the-art in inverter technology for single-phase grid connected photovoltaic (PV) systems.

Get a quote

Solar Grid Connect Inverters

Solar grid connect inverters are also called "string" inverters because the PV modules must be wired together in a series string to obtain the required DC input voltage,

Get a quote

Review and Study of Solar String Inverters for a PV System

Grid tied PV plants have the advantage of more effective utilization of generated power. Grid interconnection of PV systems is accomplished through the inverter, which

Get a quote

Luxembourg pv system connected to grid

Assuming the initial DC-link voltage in a grid-connected inverter system is 400 V, R= 0.01 O, C = 0.1F, the first-time step i=1, a simulation time step Dt of 0.1 seconds, and constant grid voltage

Get a quote

Difference Between Grid-Tied PV Inverter And

A grid-tied inverter converts the constantly varying DC solar power and feeds it into the grid. It synchronizes the frequency and the output voltage

Get a quote

String and module integrated inverters for single-phase grid connected

This work presents an overview on recent developments and a summary of the state-of-the-art in inverter technology for single-phase grid connected photovoltaic (PV) systems.

Get a quote

STEVAL-ISV002V1, STEVAL-ISV002V2 3 kW grid

A single-phase grid-connected inverter, with unipolar pulse-width modulation, operates from a DC voltage source and is characterized by four modes of operation or states.

Get a quote

International Guideline for the Certification of Photovoltaic

Photovoltaic, PV, Systems, Inverter, Field Tests, Open Circuit Tests, Short Circuit Tests, Photovoltaic Array Tests, Infrared Scan, Field Wet Resistance, Photovoltaic Array Tracker,

Get a quote

SG3300/4400UD-MV |Solar Inverter | PV Inverter from 450W to

SG3300/4400UD-MV Sungrow offers solar inverters with a high efficiency of over 99%, ranging from 450W to 8.8 MW. Besides, Sungrow PV inverters can be converted on any desired scale.

Get a quote

PV Grid-Connected Inverter | 125kW inverter

PV grid-connected inverters, Sungrow SG125CX-P2, are applicable to 1000V DC systems, reaching 125kw power output and a maximum efficiency of 98.5%.

Get a quote

Solar

Single-phase PV inverters are commonly used in residential rooftop PV systems. In this application example, a single-phase, single-stage, grid-connected PV inverter is modeled. The

Get a quote

Luxembourg pv system connected to grid

Unlike off-grid PV systems, Grid-Connected Photovoltaic Systems (GCPVS) operate in parallel with the electric utility grid and as a result they require no storage systems.

Get a quote

Introduction Of String Photovoltaic Inverter

The string-type grid-connected inverter is small in size and light in weight, and is very convenient to handle and install. In various applications, it

Get a quote

Inverter types and classification | AE 868: Commercial Solar

Central Inverter Let''s start with the central inverter, as shown in Figure 4.1. This is a PV array that consists of three strings, where each string has three series connected modules. Before these

Get a quote

Five-Level T-type Cascade Converter for Rooftop Grid

1. Introduction Rooftop photovoltaic (PV) energy conversion systems (less than 20 kW), have become a well-established technology in the industry. The most common configurations for

Get a quote

Single-Phase, Grid-Connected PV Inverter (Lookup Table-Based

In this application example, a single-phase, single-stage, grid-connected PV inverter is modeled. The PV system includes an accurate PV string model that has a peak output power of 3 kW.

Get a quote

LUXEMBOURG''''S FIRST FLOATING PV PLANT IS NOW

Can grid-connected PV inverters reduce oscillations in DC-link voltage? To address this issue, this paper presents an advanced control approach designed for grid-connected PV inverters.

Get a quote

Two-stage grid-connected inverter for PV systems

In this study, a two-stage grid-connected inverter is proposed for photovoltaic (PV) systems. The proposed system consist of a single-ended primary-inductor converter (SEPIC) converter

Get a quote

Review on novel single-phase grid-connected solar inverters:

An ever-increasing interest on integrating solar power to utility grid exists due to wide use of renewable energy sources and distributed generation. The grid-connected solar

Get a quote

A review of different multi-level inverter topologies for grid

Along with the PV string, the inverter is a critical component of a grid-connected PV framework. While two-level inverters are often utilized in practice, MLIs, particularly Cascaded

Get a quote

Introduction Of String Photovoltaic Inverter

The string-type grid-connected inverter is small in size and light in weight, and is very convenient to handle and install. In various applications, it can simplify construction and

Get a quote

6 FAQs about [Luxembourg string grid-connected photovoltaic inverter]

Why are PV inverters so popular?

As PV systems need an electronic interface to be connected to the grid or standalone loads, the PV market has started appealing to many power electronics manufacturers. Improvements in design, technology and manufacturing of PV inverters, as well as cost reduction and high efficiency, are always the main objectives, [see References 1, 2].

What is a single-phase grid-connected inverter?

A single-phase grid-connected inverter, with unipolar pulse-width modulation, operates from a DC voltage source and is characterized by four modes of operation or states. Two modes take place during the positive load current period and two modes in the negative load current period, as shown in Table 6. Table 6.

How a grid connected inverter works?

Every algorithm for grid-connected inverter operation is based on the estimation or direct measurement of grid-voltage frequency and phase angle. Both parameters are fundamental for correct operation and special care must be taken in their detection to avoid the influence of any external noise.

What is a dual-stage inverter for grid-connected applications?

Table 1. The dual-stage inverter for grid-connected applications includes a DC-DC converter to amplify the voltage and a DC-AC inverter to control the current injected into the grid. Figure 3. The DC-DC converter is depicted in Figure 3 together with the DC-AC converter and LCL filter.

Which microcontroller is used for MPPT & grid connection?

The converter performs MPPT and grid connection by means of an ARM Cortex M3-based STM32F103xx microcontroller, which is proven to be well suited for such an application. In fact, the implemented DQ axis control scheme shows excellent regulation of both active and reactive power, as is also required for low power applications in the near future.

How is inverter current transformed?

The inverter current is transformed, using Park equations, in the two components referred to the rotating DQ reference frame of the grid voltage. These components, Id and Iq, are proportional to active and reactive generated power, respectively.

Guess what you want to know

-

Philippines single-phase string grid-connected photovoltaic inverter

Philippines single-phase string grid-connected photovoltaic inverter

-

Honduras Grid-Connected Photovoltaic Inverter Company

Honduras Grid-Connected Photovoltaic Inverter Company

-

Huawei 300kw photovoltaic string inverter

Huawei 300kw photovoltaic string inverter

-

Is the photovoltaic grid-connected inverter suitable for civilian use

Is the photovoltaic grid-connected inverter suitable for civilian use

-

Bolivia grid-connected photovoltaic inverter

Bolivia grid-connected photovoltaic inverter

-

Togo grid-connected photovoltaic inverter

Togo grid-connected photovoltaic inverter

-

Photovoltaic grid-connected inverter reverse voltage

Photovoltaic grid-connected inverter reverse voltage

-

500w grid-connected photovoltaic inverter

500w grid-connected photovoltaic inverter

-

Photovoltaic DC grid-connected inverter

Photovoltaic DC grid-connected inverter

-

Sao Tome and Principe grid-connected photovoltaic inverter manufacturer

Sao Tome and Principe grid-connected photovoltaic inverter manufacturer

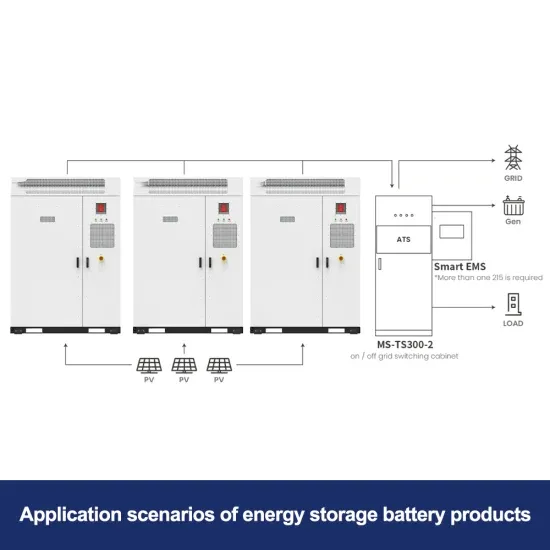

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.